|

This area is near and dear to me. Most of my lathe experience has been in spindle turning. My first lathe had a mere 2½" clearance between the center and the ways (the bed). This really limited the me to tiny bowls and it seemed to me that you had an extremely limited range of ideas for turning nice usable bowls. Since then, I have purchased a much larger lathe, with a 7" clearance, and I have discovered that techniques, such as off-center turning, can provide limitless ideas. Still, spindle turning has always been my greatest passion and led to my Magical Wand businness in The Old Traders Wand Shop. This lesson starts you off into the world of spindle turning.

Spindle turning is the term applied to all work done on a lathe in which the stock to be worked upon is held firmly between the live and dead centers. There are two methods in common use in wood turning: first, the scraping or pattern-makers' method; and second, the cutting method. Each has its advantages and disadvantages, but it is necessary that both be learned in order to develop a well rounded turner. Care should be exercised, however, that each method be used in its proper place. The first is slower, harder on the cutting edge of tools, and less skill is required to obtain accurate work; the second is faster, easier on the cutting edge of tools, and the accuracy of results obtained depends upon the skill acquired. As skill is the one thing most sought for in lathe work, the use of the cutting method is advocated entirely for all spindle turning and, with but few exceptions, for face-plate and chuck turning.

TO CENTER YOUR STOCK

If the wood to be turned is square or rectangular in shape, the best way to locate the center is to draw diagonal lines across the end of the stock corner-to-corner to make an X. The point of intersection locates the center. If it is round, you can 'eyeball' your best guess then adjust it once you start to secure it on the lathe.

Your work will be a lot easier if you resaw any rectangular stock to a square first (unless you are going to do some off-center turning too).

Another helpful process is to cut the square edges off the stock turning it into an octagonal stock rather than square. You will have a much easier time rounding it out. Mark the center before you do this.

CLAMPING THE STOCK IN THE LATHE

Take the live center from the spindle and with a wooden mallet drive the spur deep into the wood. Never drive the wood onto the live center while in the spindle because serious injury may be done the machine by such practice. When extremely hard wood is being used, it is a good practice to make saw cuts along the diagonal lines and bore a hole at the intersection, thus allowing the spur to enter the wood more freely. Wax the other end of the wood where it will be turning on the dead center (even if it has bearings).

Now, replace the live center by taking the stock and center and forcing it into the spindle by a sudden push of the hand. The tail stock is then moved about ½" to 1" from the end of the piece to be turned, having the tail spindle well back in the tail stock. The tail stock is then clamped to the bed. Turn the tail stock hand wheel until the wood is held firmly. WorkTurn the live center by hand at the same time, so that the cup, or dead center, will be forced deeply into the wood: so deeply that the live center will not continue to turn. Now turn the dead spindle back until the live spindle begins to turn freely and clamp the dead spindle fast.

ADJUSTING THE TOOL REST

Horizontally the tool rest should be set about 1/8" from the farthest projecting corner of the wood and should be readjusted occasionally as the stock diminishes in size. The vertical height varies slightly according to the height of the operator. It is even with the center of the spindle for a short person; 1/8" above for a medium person; and ¼" above for a tall person. So long as the stock is in its square form the tool rest should never be adjusted while the machine is in motion as there is danger of the rest catching the corners and throwing the stock from the machine. Also see that everything is clamped tightly before starting the lathe.

POSITION OF THE OPERATOR

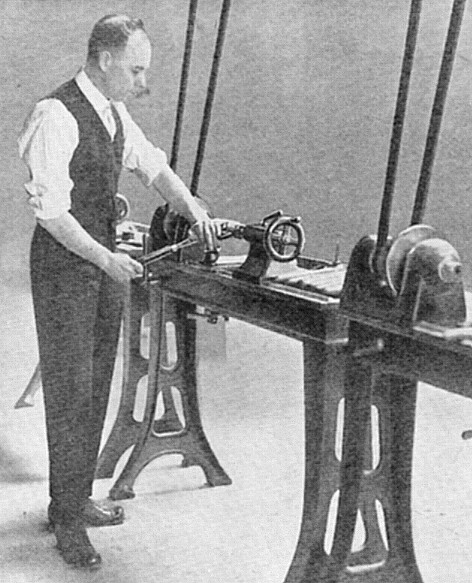

The operator stands firmly on the floor back far enough from the lathe to allow him to pass the tools from right to left in front of his body without changing the position of the feet. It may be found convenient to turn slightly, bringing the left side of the body a little closer to the lathe. In no case, however, should the tools be brought in contact with the body as the cutting operation from right to left should be accomplished by a movement of the arms alone and not the swaying of the body. (See pic)

HOLDING THE TOOLS

All tools should be held firmly, but not rigidly. The right hand should grasp the handle at the extreme end for two reasons: first, to give as much leverage as possible so that the tool will not be thrown from the hands in case it should catch in the wood; second, a slight wavering of the hand will not cause as much variance in the cuts as when held closer up to the rest. The left hand should act as a guide and should be held over the tool near the cutting edge. The little finger and the back part of the palm of the hand should touch the tool rest thus assuring a steady movement. The left hand should not grasp the tool at any time. (See pic) |

|

USE OF THE TOOLS IN SPINDLE TURNING

The correct use of the various tools used in spindle turning will be explained in detail as the steps are worked out in the sequence of operations on the exercises in later lessons.

|