Young and old enjoy croquet, a

game that has grown in popularity in recent years

... and you'll enjoy making this beautiful,

complete croquet set. Incidentally, if you are

unfamiliar with the rules, you can find layout

and playing instructions at most libraries.

The heads and handles of the mallets, the stakes

and the six balls should be made of hard wood

such as birch, maple or beech. The impact shock

of the mallets can be reduced and damage to the

balls largely prevented by inserting hard rubber

or plastic disks into the ends of the mallet

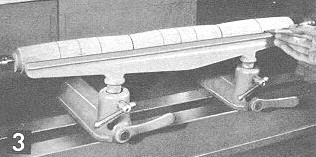

heads, see Fig. 1. Three mallet heads can be

turned at one time on the lathe by using a

24" tool rest, (Cat. No. 694) Photo No. 3.

To cut the plastic or rubber seats in the mallet

heads, mount the stock in a four jaw independent

type chuck. Cut about twelve notches or beads on

the mallet handles to provide hand grips and

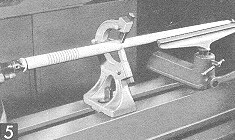

better mallet control. To prevent the handle

stock from chattering while turning, use the

steady rest as shown in Photo No. 5. The two

23" stakes can be made from 3/4"

diameter hardwood dowels, tapered on the lathe

and turned to a sharp point.

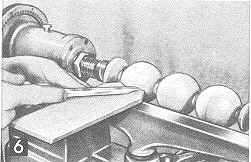

Several balls can be turned at one time on the

lathe using the scraping method with a round nose

turning tool as in Photo No. 6. Individual balls

can also be turned with a skew chisel, but should

only be tried by experienced wood turners. While

the balls are on the lathe, mark the 1/2"

wide color bands by making slight groove marks

with a diamond point tool. Varnish the balls

while still on the lathe. When dry, enamel the

six different colored bands by turning the lathe

by hand while holding the brush to the ball. If

preferred, each ball may be completely enameled.

The balls are easily removed from the ball

storage compartment by sliding them up to the

large opening. The opened portion of the ball

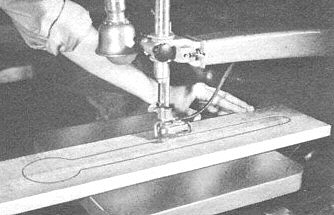

compartment is cut on the scroll saw, Photo No.

2.

The opening in the front

part of the ball compartment is cut out

on the scroll saw. |

Three mallet heads can be

turned at one time on the lathe by using

an extra tool support base and a Cat. No.

694 tool support. While stock is in the

lathe, mark off the handle hole position. |

To prevent chattering of

the long mallet handles while turning,

use the No. 948 steady rest. |

If you feel you are well versed on the

use of the skew chisel, you can turn the

balls individually using the cutting

method. |

|

All parts of the rack are made

of hard wood or exterior plywood. See complete

details of parts in the line drawing.

The nine metal arches are bent to shape from

3/16" mild steel wire as indicated in Fig. 5

of the line drawing. Each arch requires a piece

of wire 28-1/4" long.

Finish the balance of the project with a sealer

and a coat of spar varnish and enamel the hand

grips on the mallets to correspond to the ball

colors.

BILL

OF MATERIALS

| No. of

Pieces |

Name |

Size |

| 6 |

Mallet

Heads |

2

x 2 x 8 |

| 6 |

Mallet

Handles |

1

x 1 x 26 |

| 12 |

Hard

Rubber or Plastic Pads (Optional) |

1/4

x l-5/8 diam. |

| 6 |

Balls |

3-1/4

diam. |

| 2 |

Stakes

|

3/4

diam. x 23 |

| 1 |

Base

(B) |

3/4

x 8-1/4 x 2O |

| 4 |

Leg

Stretchers (C) |

3/4

x 3 x 7-1/2 |

| 1 |

Back

Upright |

3/4

x 5 x 28-3/8 |

| 1 |

Ball

Compartment Front |

3/4

x 5 x 23-1/8 |

| 1 |

Top

Mallet and Stake Support (A) |

3/4

x 3-1/8 x 2l |

| 8 |

Flat

Head Wood Screws |

No.

8 x 1-1/2 |

| 9 |

Wire

Arches |

3/16

diam. x 28-1/4 |

|

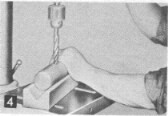

A 3/4", Cat. No. 872,

machine spur bit is used to drill the

handle holes in the mallet heads - use a

V-block to steady the stock. |

Three or more balls can be

turned at one time on your lathe using

the scraping method with a round nose

turning tool. Note the wood template for

checking the roundness of the balls being

turned. |

|