|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

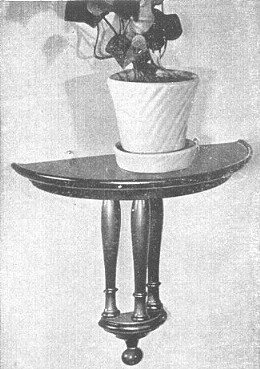

Build this

Turned Shelf

Here is the original article straight

from

Book No. 4509, PRACTICAL DELTA PROJECTS

NEW & NOVEL THINGS TO MAKE,

BOOK 9

DELTA MFG. DIVISION

USE

the full-size pattern when turning,

picking off the dimensions directly with

calipers or dividers as required. The top

is glued up in two pieces with paper at

the joint and then glued, also a paper

joint, to a backing block about 6 inches

in diameter. After turning the under

side, the work can be reversed and

mounted directly to faceplate for the

final operation of recessing the rim. The

spindles are standard turnings. Two solid

and two split spindles are needed to make

a pair of shelves. Stock for the bottom

turning can be mounted on a backing

block, or, if cut an inch longer than

finished size, can be mounted directly to

faceplate.

The stock should be in two parts with

paper at the joint so that the turning

can be split when finished.

|

Holes for the spindles should be drilled

before the faceplate turnings are split

apart. Each shelf is hung by means of two

metal hangers, bradded to the back of the

shelf. The finish should be natural,

using clear varnish or lacquer. Also

attractive with a shellac and wax finish.

If a soft wood is used in the

construction, the shelf will be pleasing

in bone white shaded with a warm brown

wining stain. |

|

| *

* * Click on the drawing above to download

full size drawing in an Adobe Acrobat pdf file.* * * |

*********** WARNING***********

Read my page on safety

before building this item.

|