|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

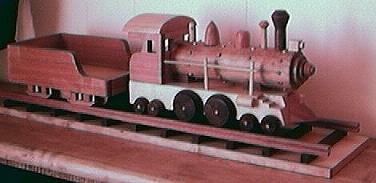

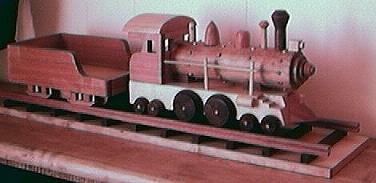

Detailed

Toy Wooden Train

Here

is one of my finest 'toy' projects. It is not

designed for hard play but rather as a keepsake.

My four year old son loves his. He does play with

it, ever so kindly, on occasion

but mostly leaves it on display atop his

bookshelf.

It is my own design taken from a picture of an

old toy. This project is only for experienced

woodcrafters.

I did not give a lot of detail on this page as

you should be quite capable of building from the

drawings

if you are skilled enough to complete this

project. It requires great precision and skill to

end up with a fine project.

Head-on elevation

drawing of the engine. |

Here comes a powerful steam

engine down the tracks!! Bring a

touch of nostalgia from the days

when steam engines thundered

across this young country and

united the East Coast with the

West coast. You can almost hear

the steam whistle blowing when

you look over the details of this

steam giant. (Check out my steam

whistle plans too and you CAN

hear them.) This six axle beauty

will get many wonderful comments

from your child's friends and the

parents too. A variety of good

hardwoods will lend good lines to

the unit. Use a dark wood, such

as Black Walnut, for the wheels

and the boiler.Use a light wood,

such as Maple or Birch, for the

bases and use a redish wood, such

as BlackCherry or Rosewood, for

the engine cab and tender sides.

The train is designed to a scale

of about 1/16th.

The overal sizes of the completed

item are as follows:

Display base

:

Engine :

Tender : |

24" long x

4" wide x 1"

tall.

24" long x 4"

wide x 1" tall.

24" long x 4"

wide x 1" tall. |

|

| Make the

boiler from a dark wood. Turn the

first two 'steps' on the front of

the boiler as part of the turned

boiler. The third step (G) should

be turned seperately and from a

medium color wood. To best locate

the center of your starting

stock, always draw lines from

corner to corner. To minimize the

amount of wood to be cut away,

cut a small bevel off each edge

too but be craeful that you do

not cut off too much and reduce

the size of the final rounded

stock. |

Locate center of

your turning stock |

| The 'cow pusher' for the

engine front is no doubt the

hardest part to cut as it

invloves multiple angle-compound

cuts. I used a straight bit in my

router to cut the steps in the

front of the engine |

Marking the cuts

for the cow pusher. |

| base then carefully squared

up the cuts with an Exacto knife.

Drill a small pilot hole all the

way through the center of you

turning stock before shaping the

wheels so the axle holes will

stay centered later. There's a

lot of detail in the tender

trucks (wheels) but notginh too

cimplicaed or tricky. |

|

| |

|

| |

|

|

Right click on any drawing,

above, for the full size drawings as an Adobe

Acrobat (pdf) file..

|