| TheWoodcrafter.net |

Copyright © 2004. |

| My Basic Projects |

| The Retro Section |

| Jr. Woodcrafter |

| My Work |

| Detailed Plans |

| About |

| Lathe Work |

| Safety |

| Hints |

| Pic Gallery |

| Links |

| Search |

| Home |

| Birdhouses |

| Guest Book |

| Contact Us |

|

|

||||||||

|

Here is the orginal article from the

January - February 1955 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

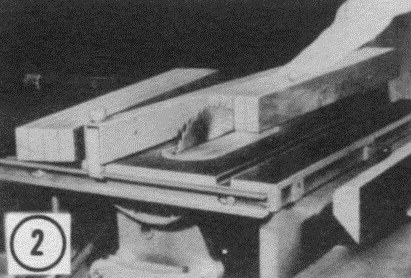

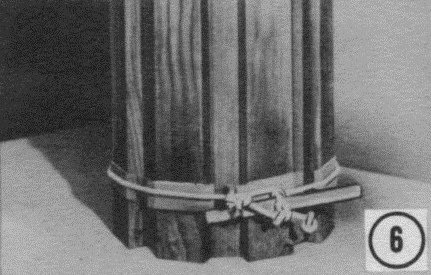

The shell can be glued together with a commercial type strap clamp or rope tourniquet as shown above. Use a good husky rope for this purpose. Paper pads will prevent the rope from marring the stock. |

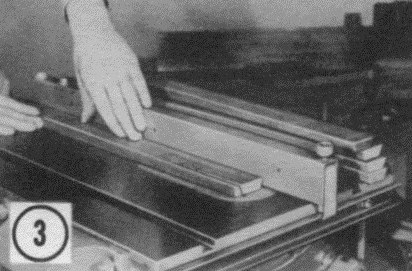

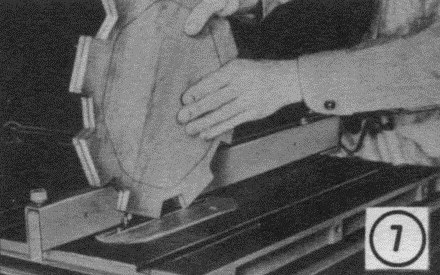

After cutting the top cap to conform to the outside shape of the base, make the first cut of the rabbet by running the stock on edge. |

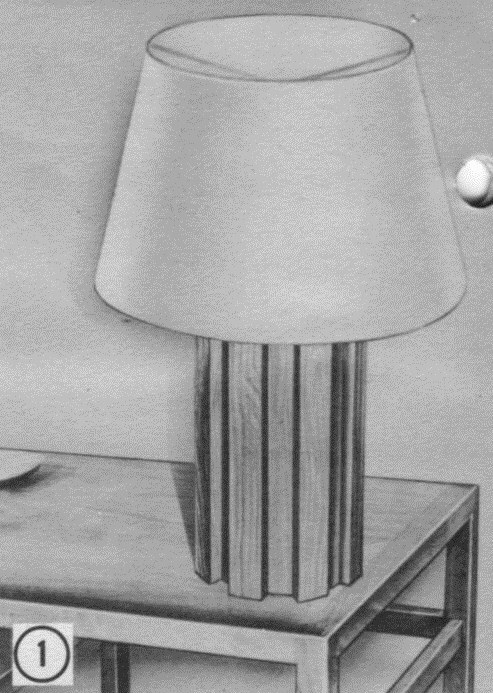

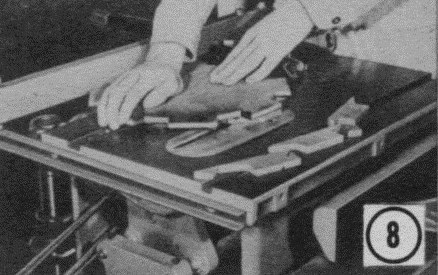

The cheek cut of the rabbet is made with stock laying flat. Rip fence is used as a stop and mitre gauge for pushing piece through the blade. |

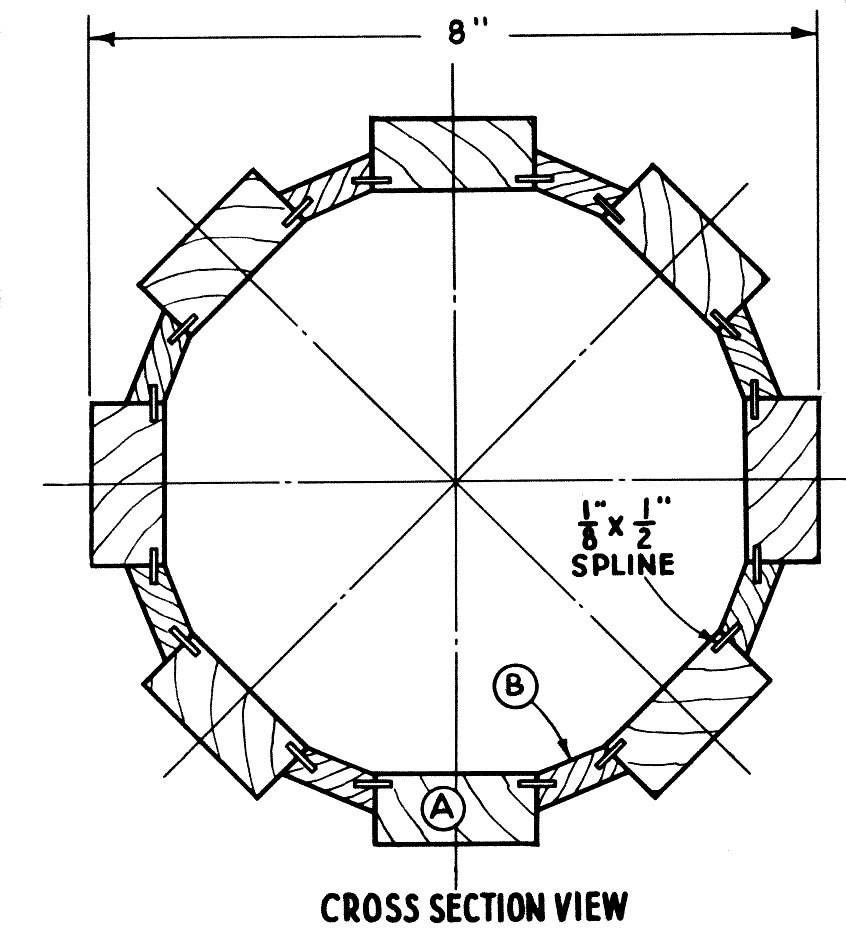

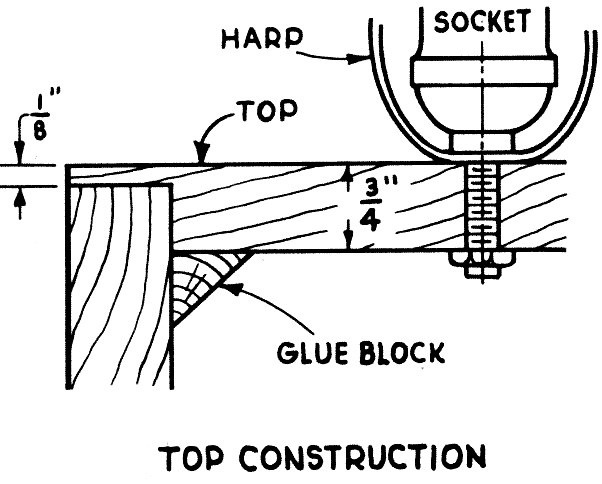

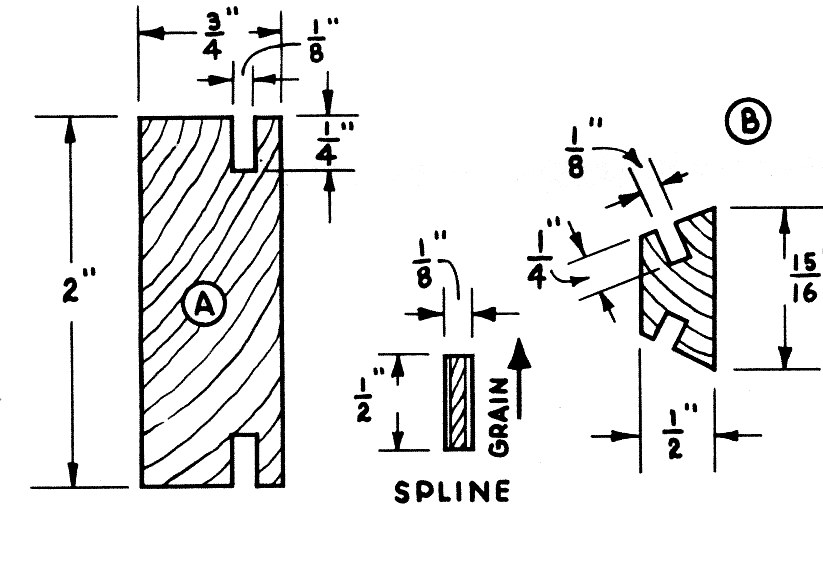

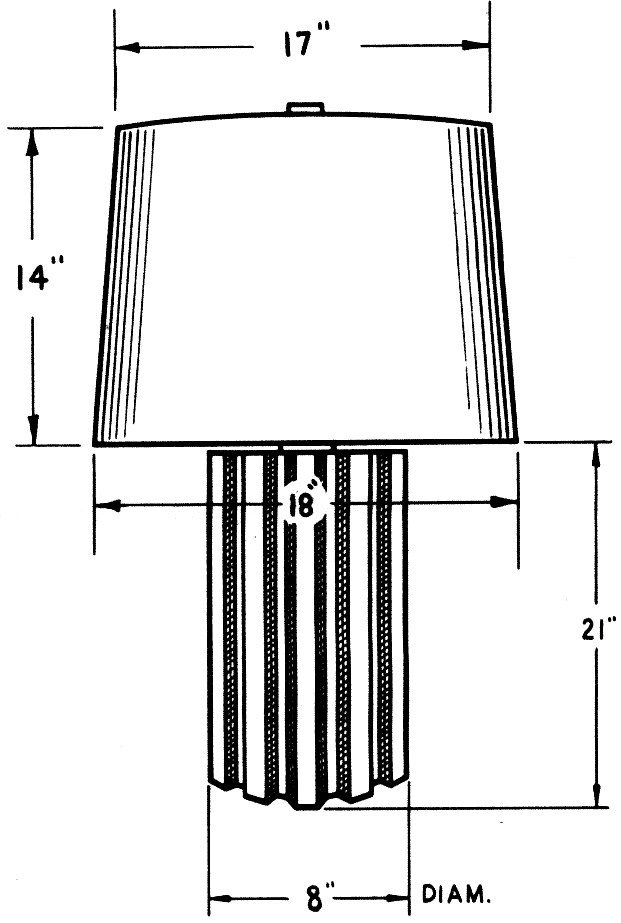

Right-click here to download the drawing as an Adobe Acrobat (pdf) file.

* * * * Click on the drawings above to download a higher resolution picture. * * * *

*********** WARNING***********

Read my page on safety before building this item.