|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

Here is the original article from the

January - February 1955 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

|

|

|

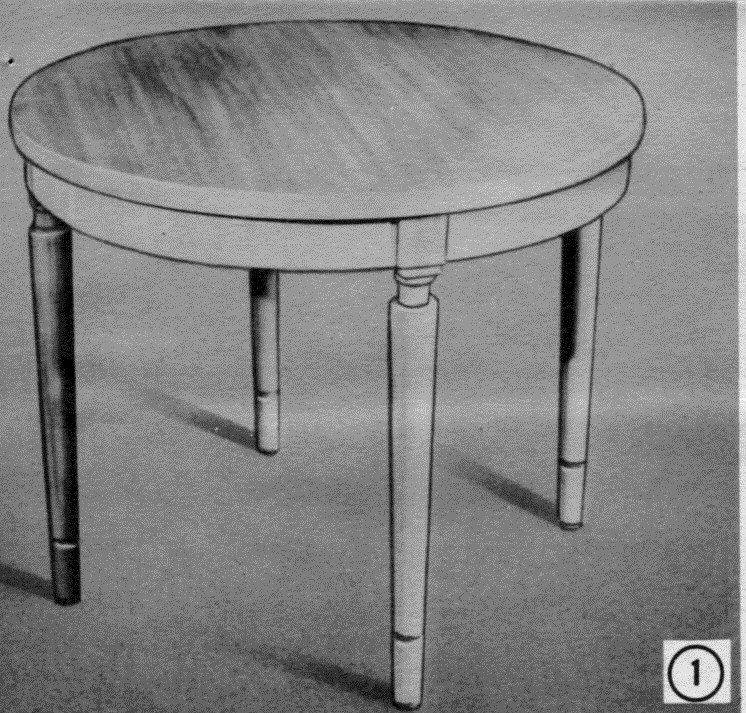

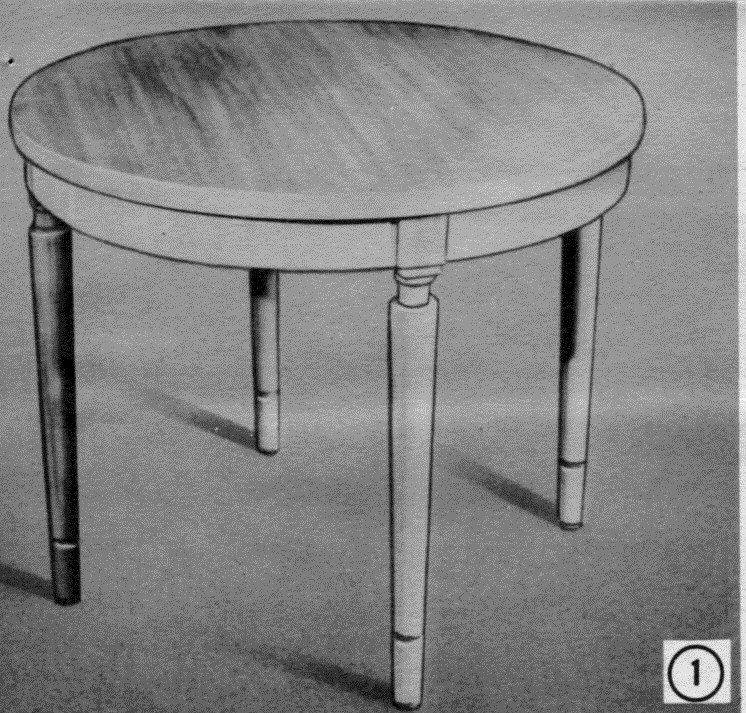

A beautifully styled round table for the craftsman who prefers the more intricate designs of traditional furniture. This is another piece in the Whitcomb traditional series. A matching lamp will follow in the next issue of the Deltagrarn.

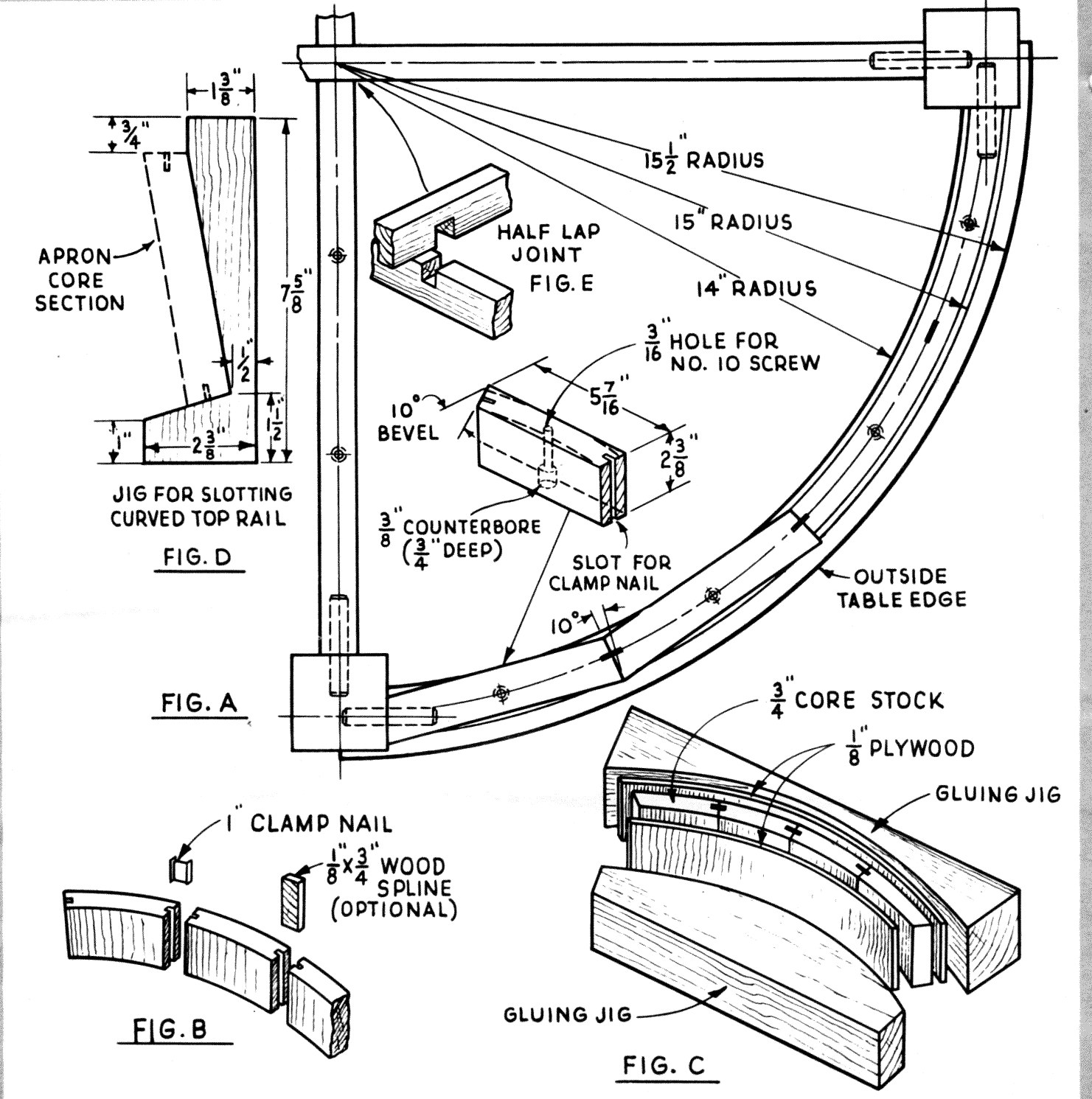

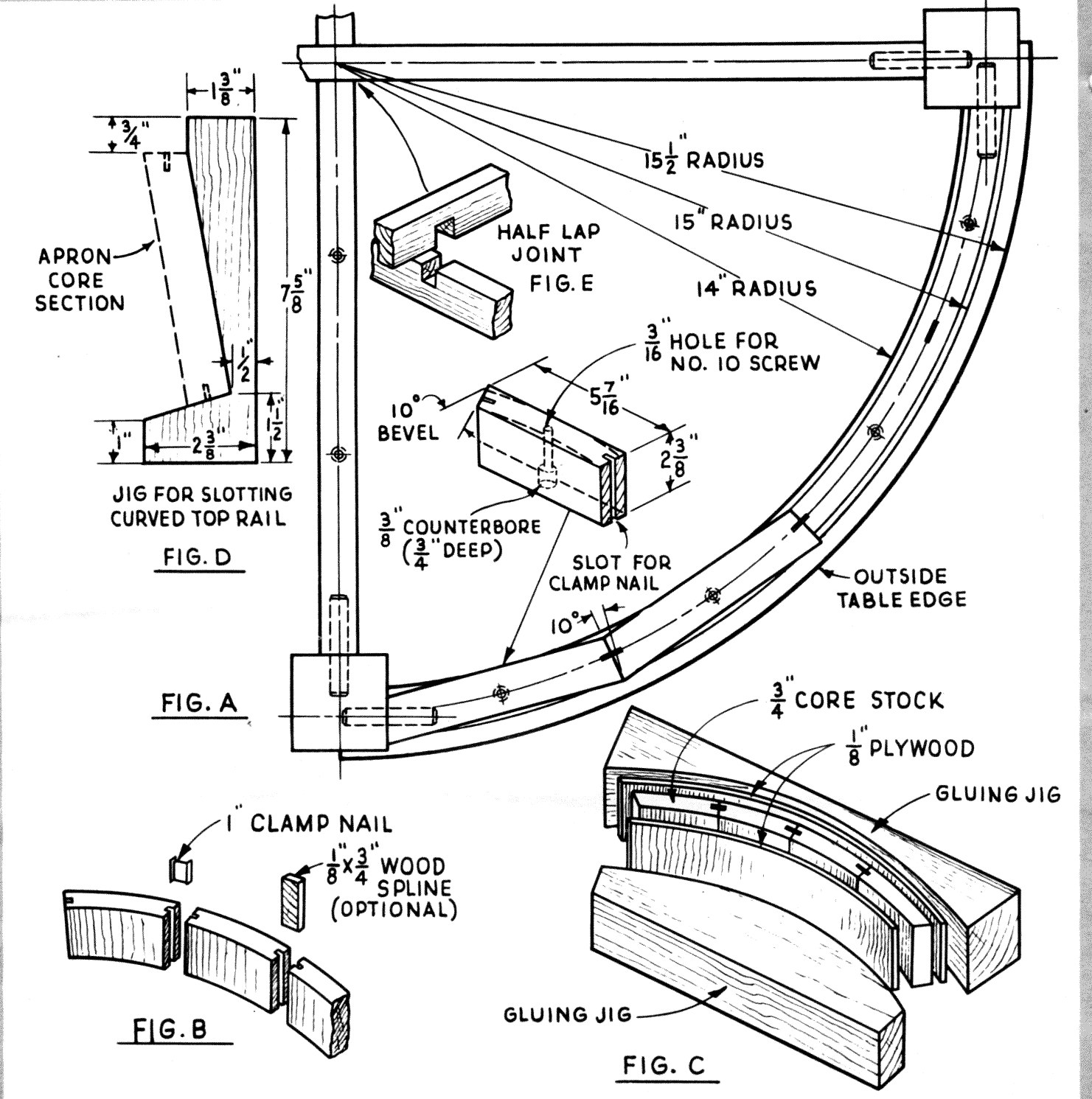

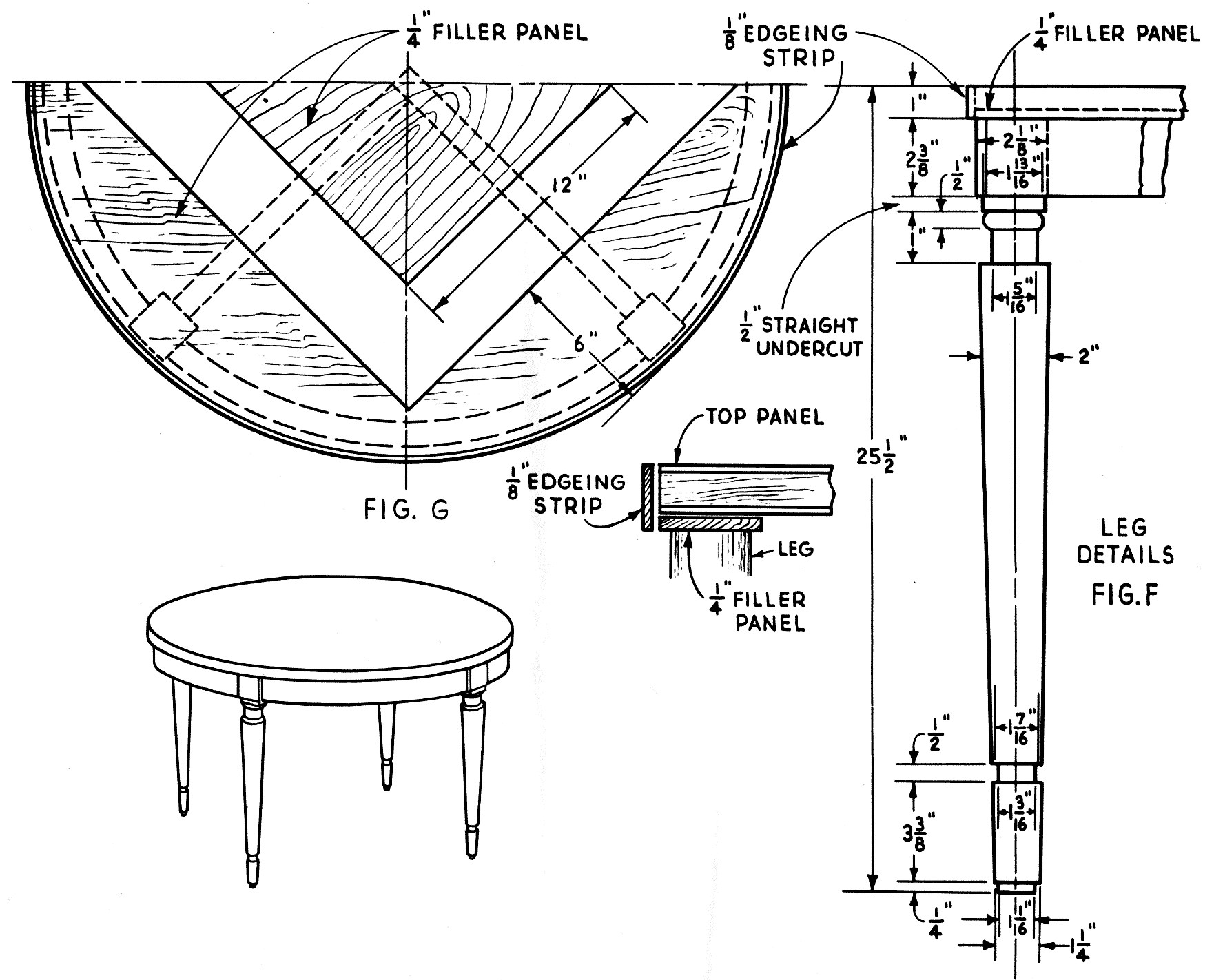

Since the curved apron of this table requires a lot of fitting and gluing, let's begin by making quarter sections of a full-size layout on a spare panel, same as Fig. A. Note that each quarter section of the core stock is made of four pieces of stock (basswood or gum) with slot in each to receive a wood spline or metal clamp nail Fig. B. Make the end pieces longer for later fitting. After the four sections are glued together, cut a two piece form (with the inside and outside radii of the apron) and glue on a 1/8 inch piece of plywood to both the inside and outside curves of the core stock, Fig. C. When glue is thoroughly dry, cut and fit to match your layout. |

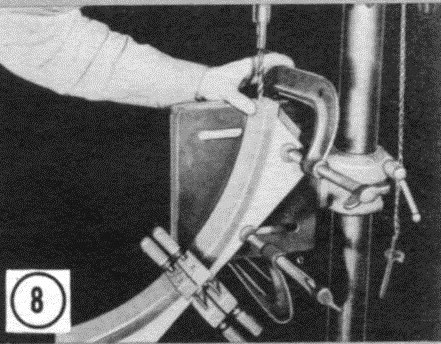

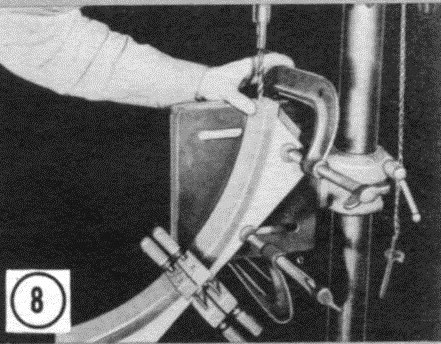

Bore holes in the ends for dowels as shown in photo No. 8.

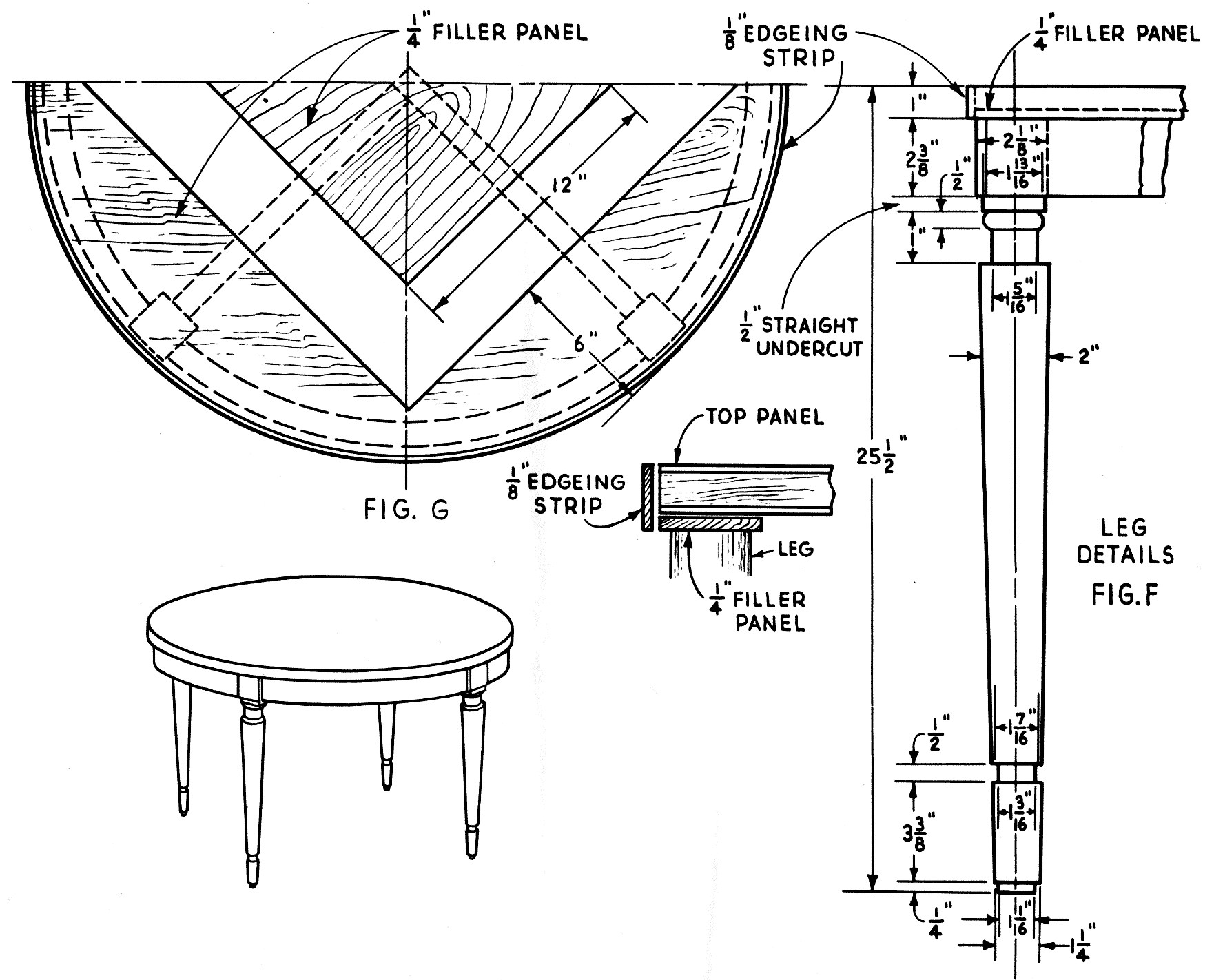

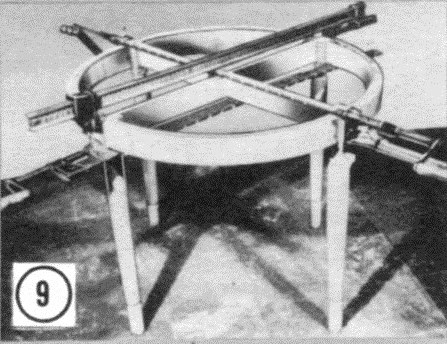

Center cross braces will stiffen the table considerably. These are made of ¾ x 2” stock half lapped at the center and doweled to the legs (see quarter section). The four legs are made of 2-1/8 X 2-1/8 stock turned to the design shown in Fig. F. Be sure to sand each leg thoroughly with 2-O and 4-0 garnet paper, while in the lathe.

The ¾ inch plywood top (one side good) is edge banded with a 1/8 x 1 inch piece of solid stock. Note the ¼ inch spacer plywood for building up the thickness of the top (see Fig. G).

Sand entire project with 2-O and 4-0 garnet "paper cleaning off all sand dust before applying two thin coats of white shellac (sanding between coats with 6-0 garnet paper) and follow with a coat of rubbed effect varnish. |

|

|

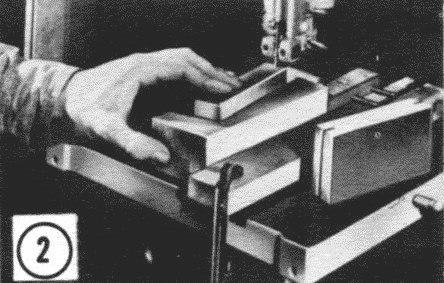

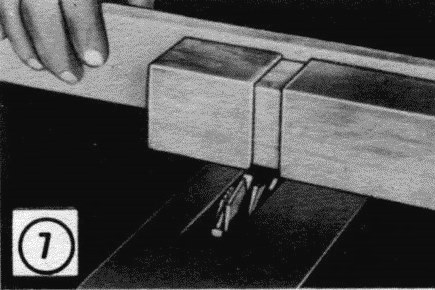

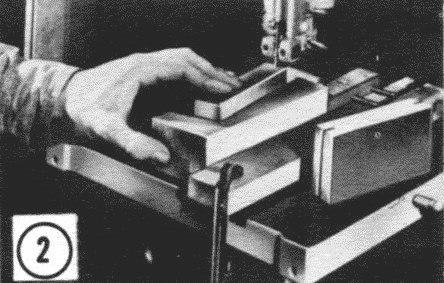

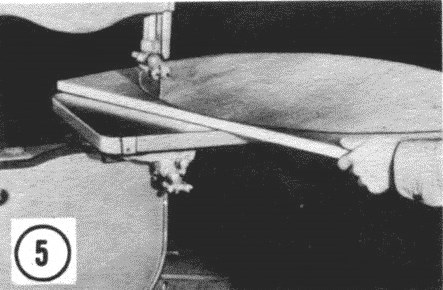

Slots are required in the core stock for the steel clamp rails. These are made on the circular saw with an extra fine gauge blade, but can be cut on the band saw as shown above.

|

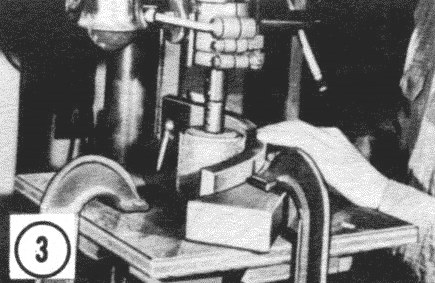

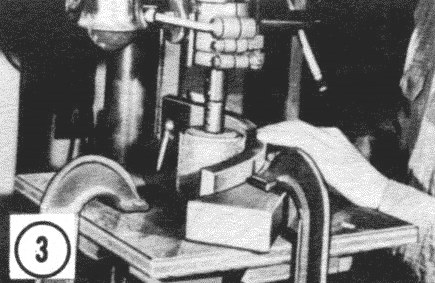

For a good gluing job of the outer plywood on the aprons, sand the core stock on the drill press with the 3 inch sanding drum mounted In the router spindle.

|

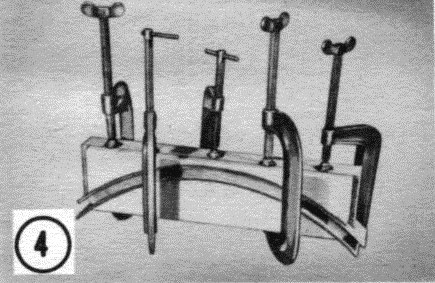

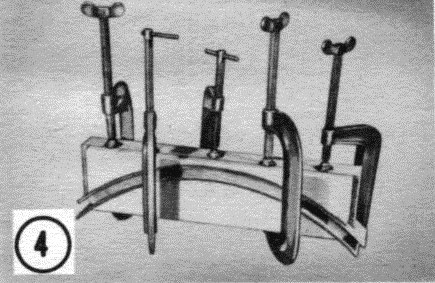

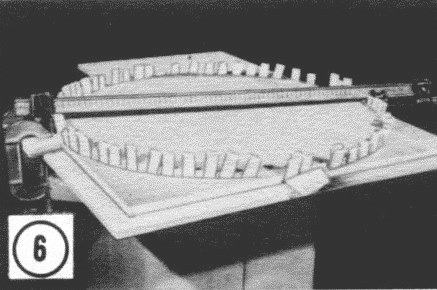

Hand screws or C-clamps are used in gluing the plywood onto the aprons. Form blocks are made of scrap stock big enough to cover the width of the apron.

|

|

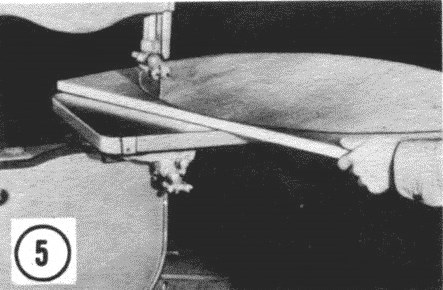

Top of table can be cut on either the band saw or scroll saw. Note: Make allowance for edging strip when laying out the circle. (See Drawing.)

|

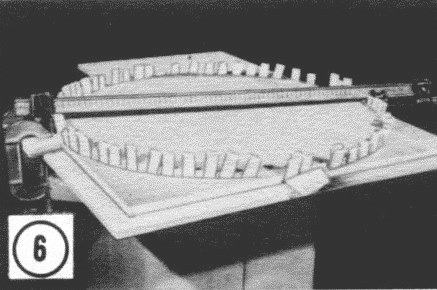

By making use of the curved surplus pieces of stock cut from the circular top nailed to a larger piece of plywood, the edging strip can be easily glues and clamped to the plywood top as shown above.

|

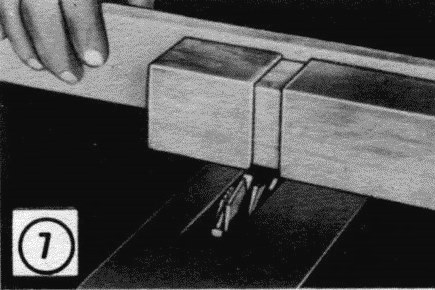

Undercut (Fig. F, page 11) of the legs is made with two outside and two inside cutters of the dado head on the Circular saw.

|

|

Best way to bore the dowel holes in the curved aprons is on the drill press with a supporting black as shown in above photo.

|

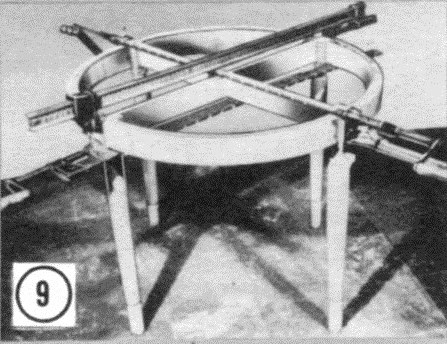

Clamp the crossrails of the table with bar clamps, this in turn tightens the curved aprons at the same time.

|

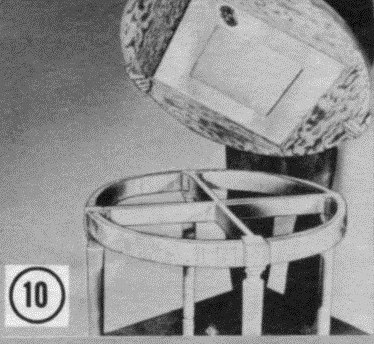

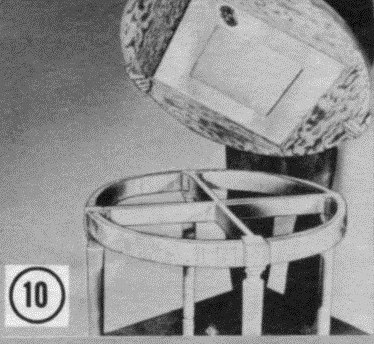

The above photo shows the base assembled with the top ready to be screw fastened to the base.

|

Right-click here to download the drawing as an Adobe Acrobat (pdf) file.

* * * * Click on the drawings above to download a higher resolution picture. * * * *

*********** WARNING***********

Read my page on safety before building this item.

|