|

Modern Wall Desk

|

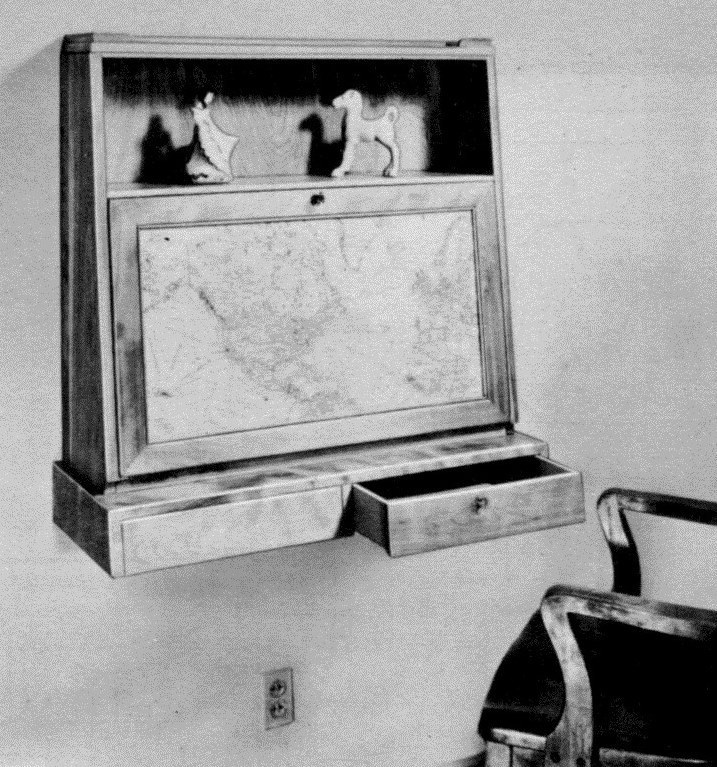

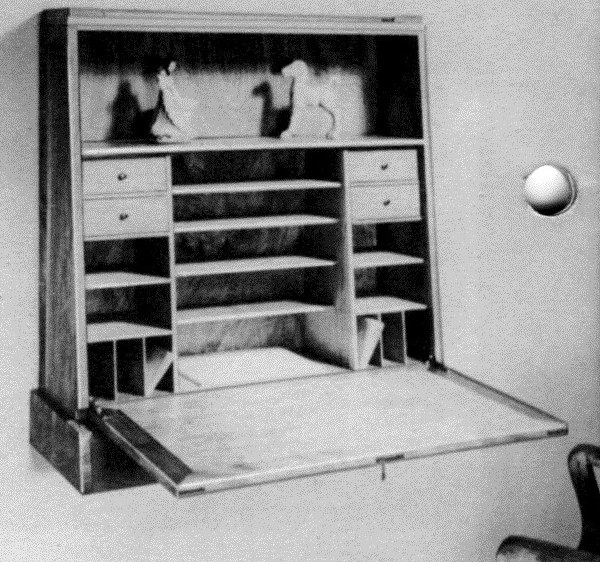

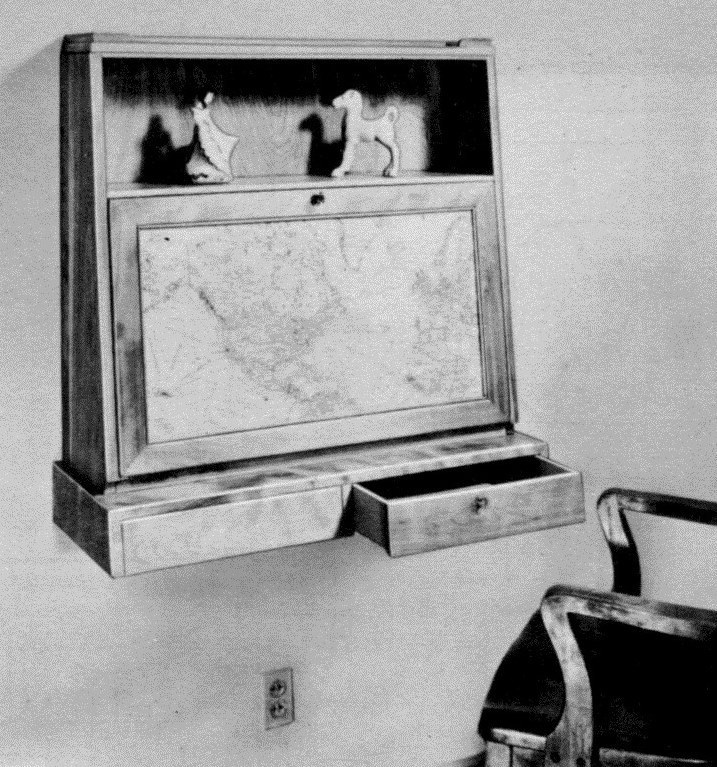

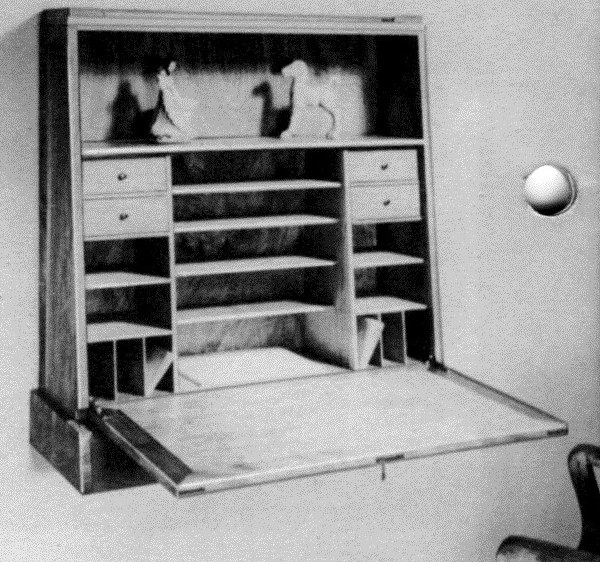

Whether it's homework, letter writing or your project planning, the whole

family will enjoy using this space saving wall desk. Its decorative beauty is sure to draw a long "O~O-Oh" from everyone.

The knick-knack shelf, two roomy base drawers, four additional inside drawers and ample pigeonhole space provide practical utility. To add a final distinctive flair, a map, photo or printing can be inserted in the hinged desk top.

Birch wood was used on the entire project except for the drawer bottoms and picture mounting board. Plywood could be substituted and the cored edges covered with the new type wood tape now available. Study the drawing carefully and take notice of the various grooves required before you assemble any sections.

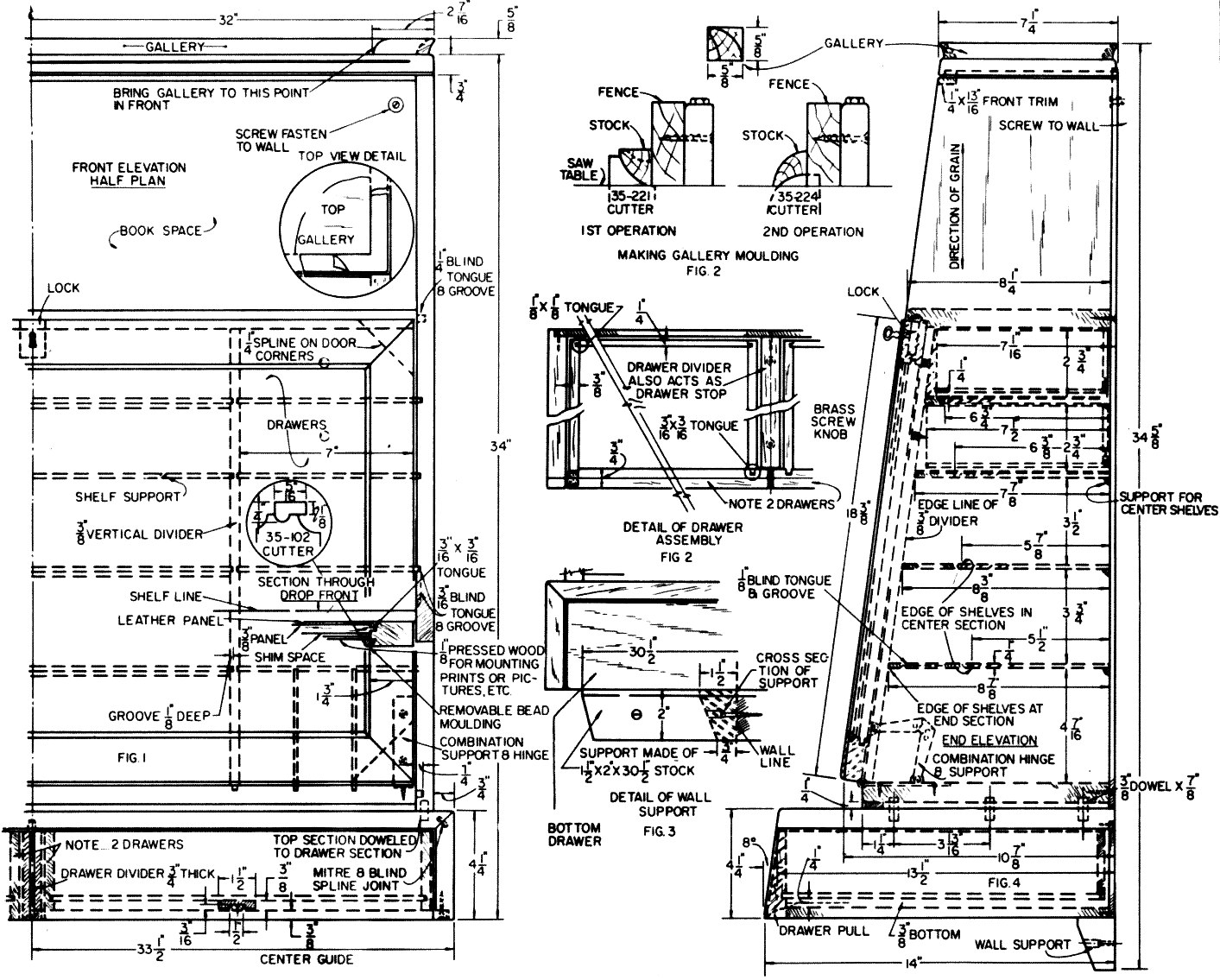

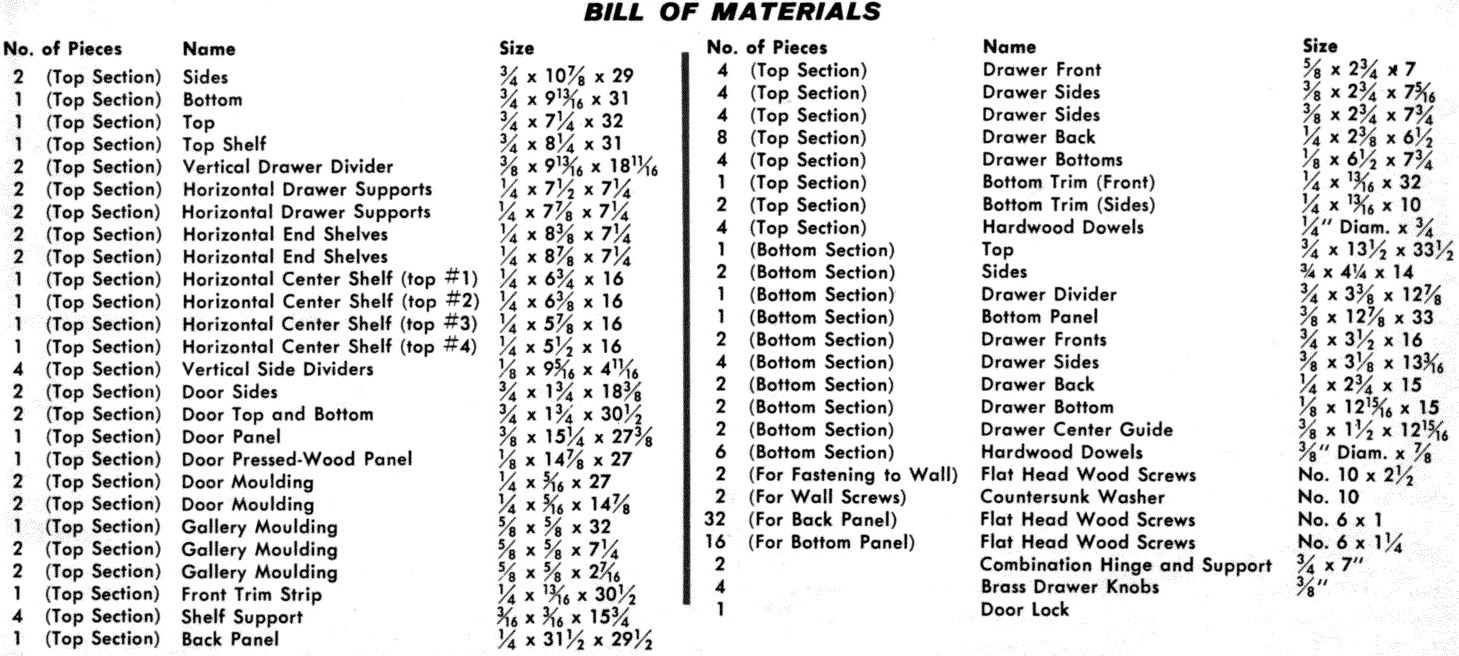

Make the sides of the upper section by cutting the pieces to correct length as indicated on the drawing. If wide enough boards are not available, glue the stock together using the Delta No. 35-131 glue joint cutters. A ¼ x ¼ inch tongue is made at the top while a ¼ x ¼ inch blind groove is used to assemble the bottom board to the sides. Make ¼ x ¼ inch blind grooves in the side pieces for the shelves. A ¼ x ½ inch rabbet is made on the back to receive the back panel.

The sides, top and bottom can be glued and assembled without the shelves and partitions, since these can be inserted from the back later.

The top shelf is made of ¾ inch stock with ¼ x ¼ inch tongue on each end, and a rabbet cut on an angle on the front edge to support the door (see drawing). Blind grooves are made on both sides of the uprights. Note that the center shelves vary in width so the grooves will have to be made accordingly.

All drawer fronts are tapered at 8°, all other parts are made in the conventional manner (see drawing for details). The door is made of ¾ x 1¾ inch solid stock with two grooves on the inside edge. One of these grooves is for the writing surface panel and the other to hold the pressed wood used for mounting pictures, maps, etc. (see cross section Fig. #1 of drawing). Splines ¼ inch thick are used on the corners of the door. The spline grooves should

be cut 1¾ inches deep after the door has been assembled.

|

|

(Photo No. 2)

(Photo No. 3)

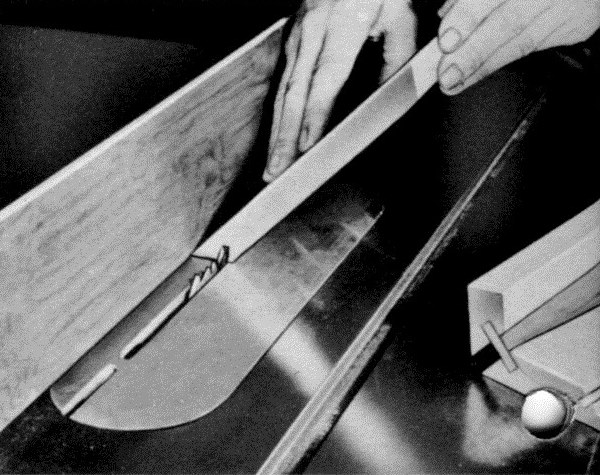

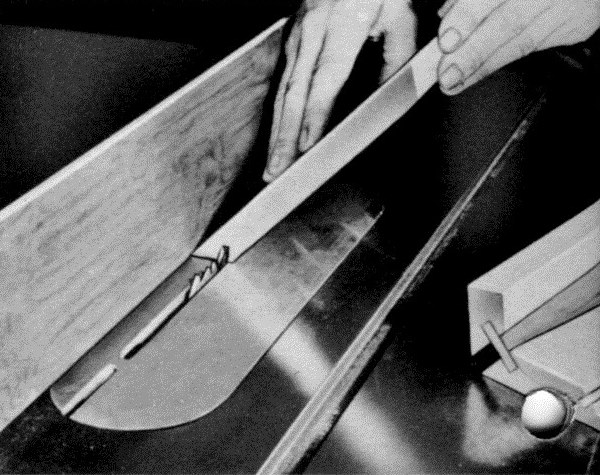

¼ inch spline grooves on top and side pieces of the base section are made on the circular saw Using the outside cutter of the Delta No. 34-333 Dado Set. Note the auxiliary wood facing fastened to the rip gage to insure no gap between the table and the fence while making the groove in the mitered end of the stock.

(Photo No. 4)

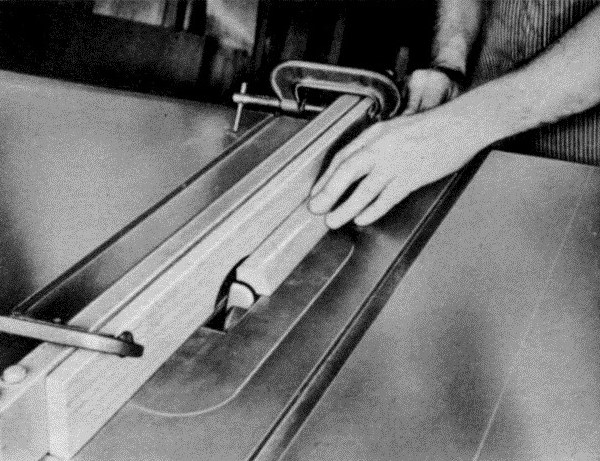

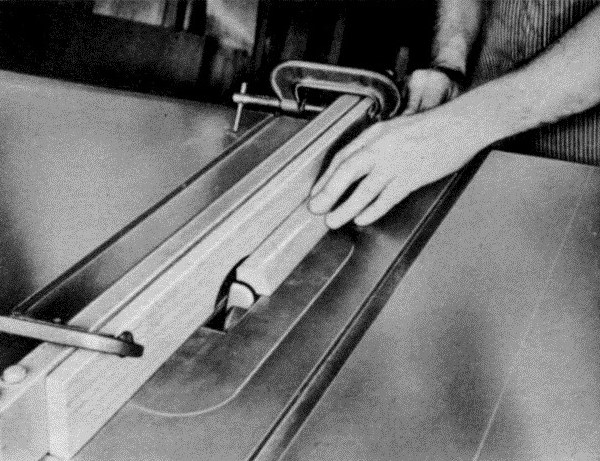

The gallery moulding for trimming the top of the desk is made in two operations. The second operation is being made on the circular saw with the Delta No. 35-224 knives mounted in the No. 265 cutter head.

|