|

Because

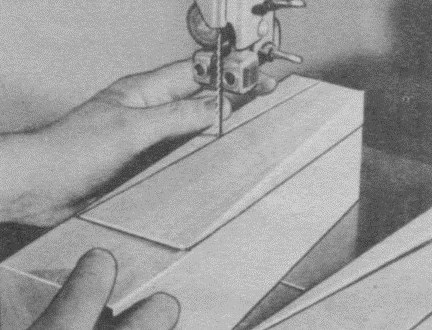

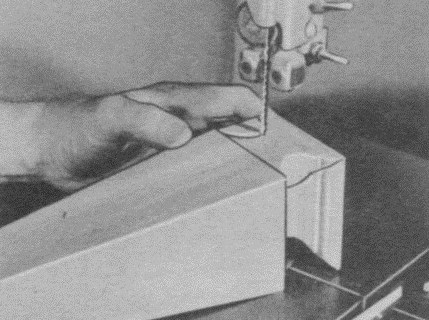

(Photo No. 2)

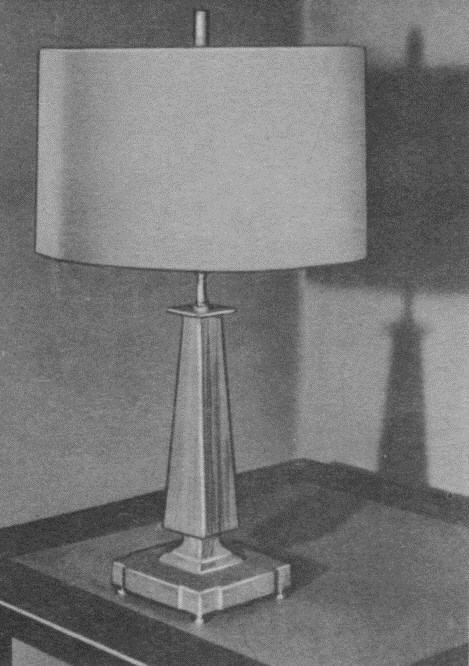

By marking the tapers on the lamp post they

are then cut as shown on the band saw.

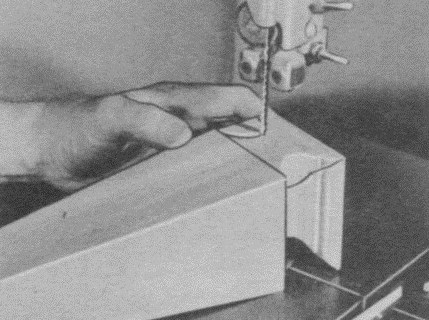

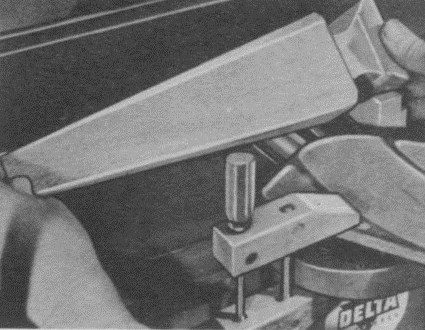

(Photo No. 3)

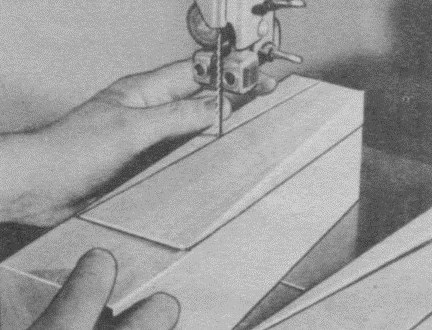

The moulding effect on the lamp post is cut

on the band saw using a 1/8 inch wide blade.

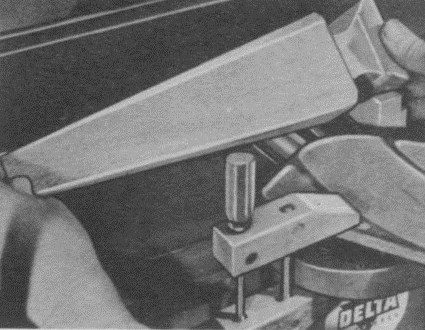

(Photo No. 4)

The corner chamfers of the lamp post are

made with the use of two blocks (Fig. No. A) and

and lowering the front and rear tables of the jointer.

|

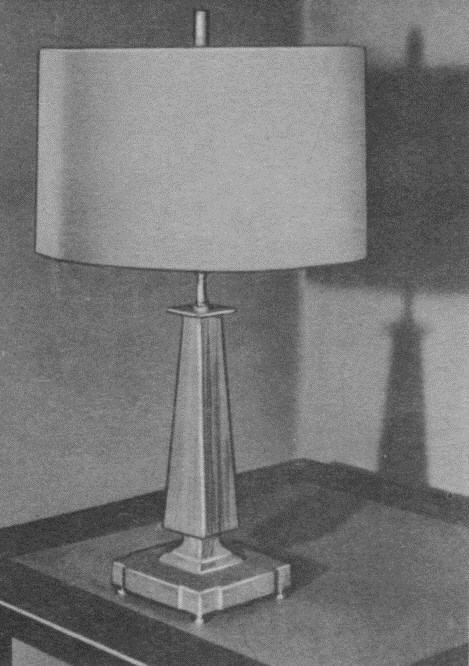

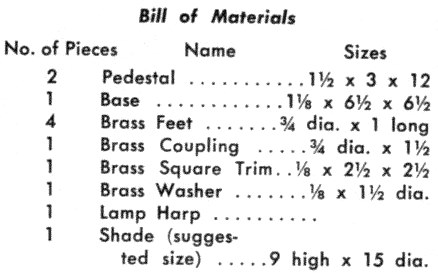

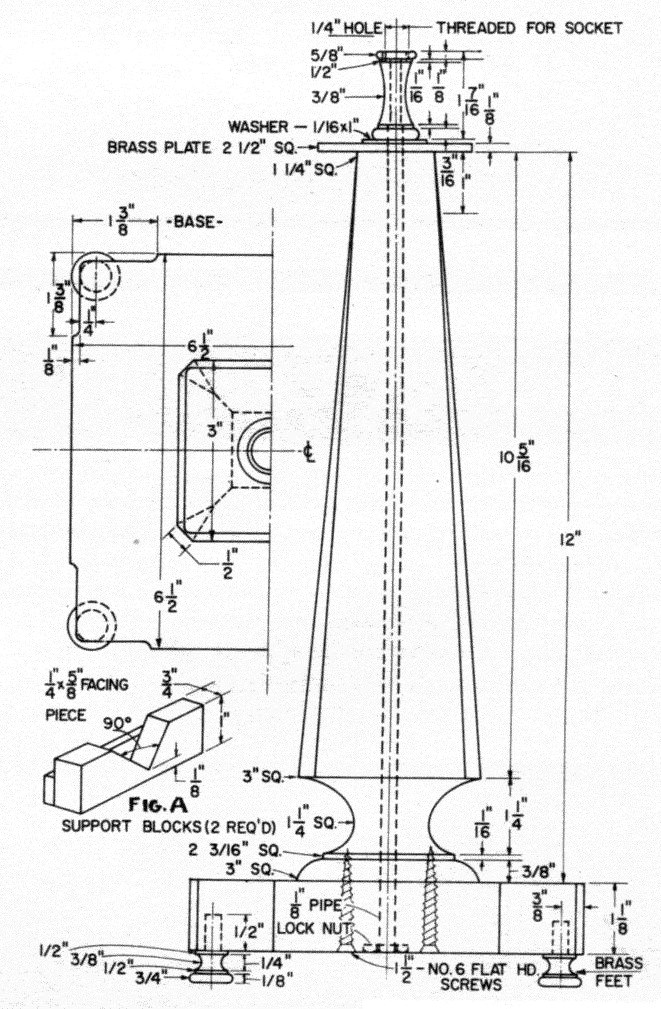

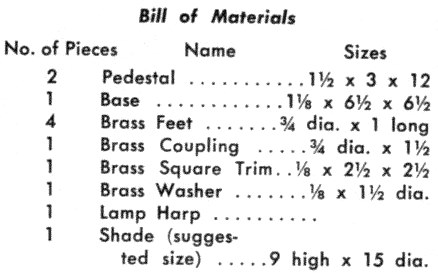

This table lamp of Grecian styling will blend with the decor of any living room. Its unique design lends itself nicely to either traditional or modern furnishings. Black walnut combined with brass, or any of the pular blonde woods combined with aluminum, make a truly distinctive and beautitliil lamp.

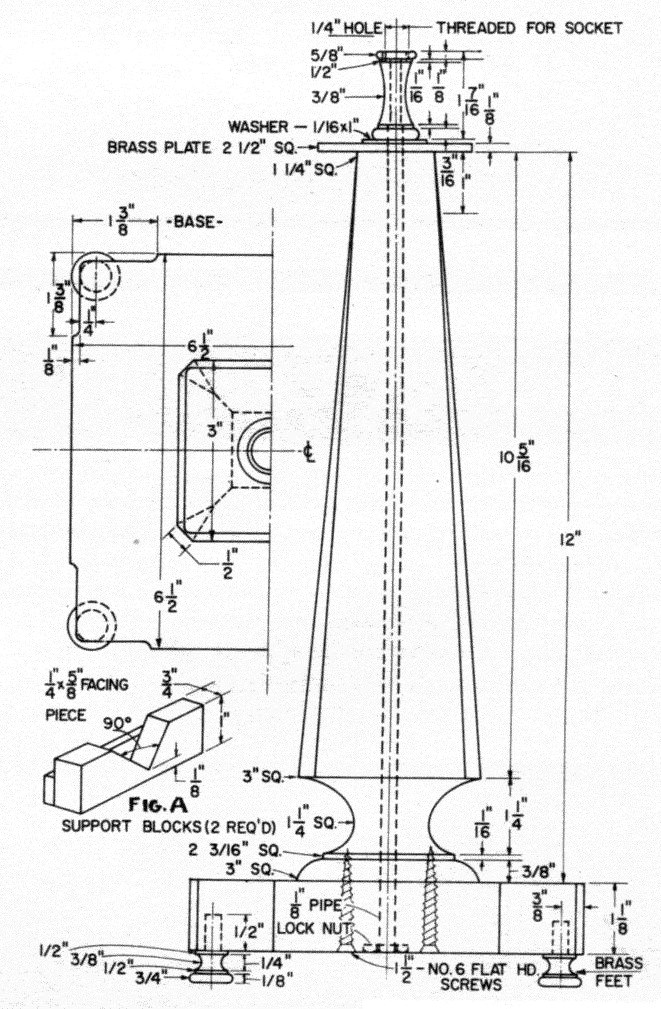

The lamp column is made up in halves. A 3/16 inch deep x 3/8 inch wide groove is cut in each section before they are glued together. This will form a hole for the 1/8 inch pipe that houses the wires leading to the lamp socket. The actual shaping of the iamp column involves compound band sawing. Photo Nos. 2 and 3 show this operation being performed.

The brass or aluminum feet, harp support and ?nial are turned on the lathe, using tungsten alloy tipped turning chisels. If you prefer, these parts together with the ;ight fixture and pipe can be purchased from your local electrical dealer.

If walnut is used in constructing the lamp apply a walnut filler and seal with lacquer when finishing. After it is dry rub and wax.

|