| TheWoodcrafter.net |

Copyright © 2004. |

| My Basic Projects |

| The Retro Section |

| Jr. Woodcrafter |

| My Work |

| Detailed Plans |

| About |

| Lathe Work |

| Safety |

| Hints |

| Pic Gallery |

| Links |

| Search |

| Home |

| Birdhouses |

| Guest Book |

| Contact Us |

|

|

||||||||

|

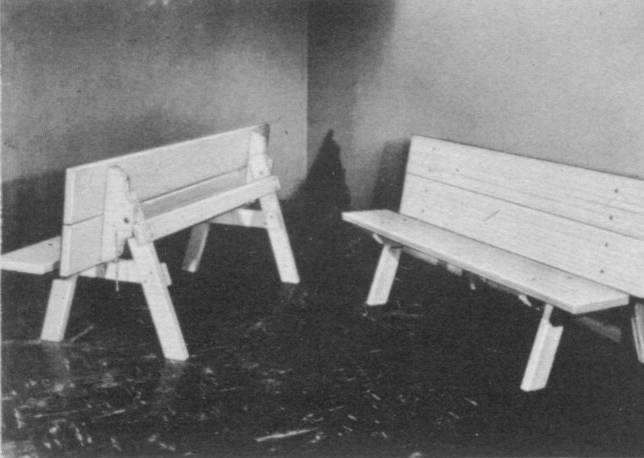

Dual Purpose

Picnic Table and Benches

Here is the orginal article from the

November - December 1959 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

|

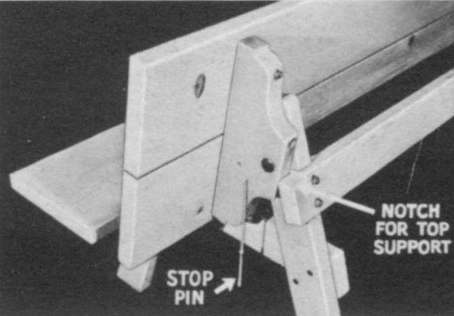

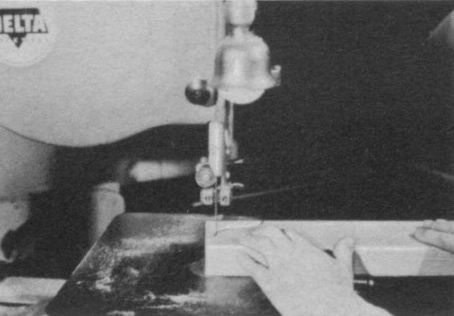

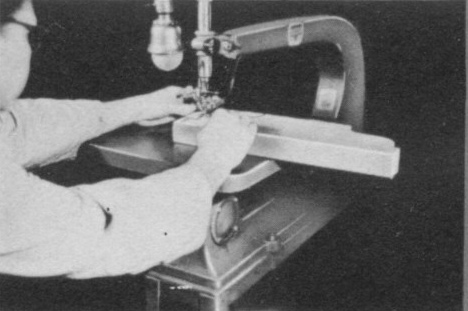

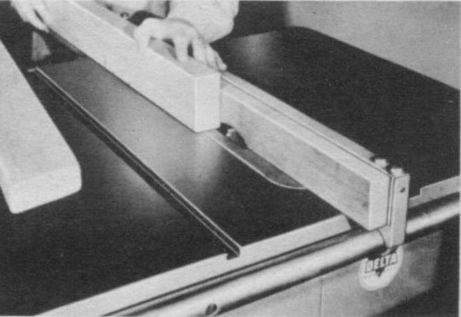

It's a picnic table! It' s a pair of benches! You get double-use, double-fun, from this unusual combination picnic table that readily converts into two attractive benches. Only standard materials available at any local lumber dealer are used in its construction. Cut the table and seat legs and the horizontal seat supports from 2 x 4 stock. Angle cuts on these pieces are made on the saw by setting the miter gage at 72o. Be sure to round off the top corners of the table legs to allow the table top to swivel, (see drawing ) . Also make a 3/16 inch deep notch in the table leg to receive the rear 2 x 4 stretcher. This stretcher is bevel notched on each end (Fig. No. 3) to support the table top when the top is in a horizontal position (see Fig. Nos. 1 and 4) . |

Right-click here to download the drawing as an Adobe Acrobat (pdf) file.

* * * * Click on the drawings above to download a higher resolution picture. * * * *

Read my page on safety before building this item.