|

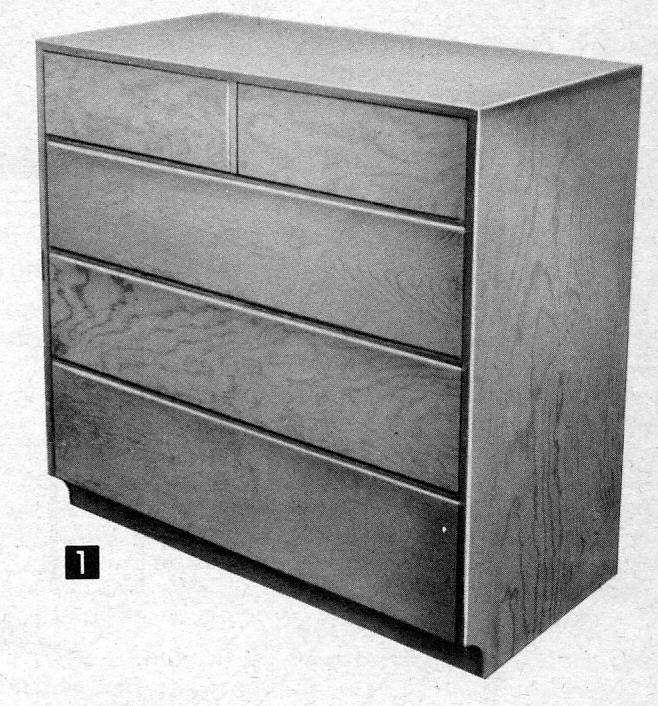

Chest of Drawers

for a Child's Room |

Just the right size for a child's room, this chest of drawers is extra safe because it has no knobs, hardware or sharp corners to injure youngsters.

The entire project is made of lumber core plywood except for the drawer bottoms and back panel which are 1/8" hardboard. Cut two pieces for the sides 18 X 34¼", this includes ¼" for the top tongue. Make four ¾" wide ¼" deep blind dadoes for the drawer slide frames, see drawing Figs. 3, 4 and 5 and Photo No.2. The blind dadoes should end about 1" from the front edge of the side piece. A ¾" x ¼" groove is also made for the front base stretcher, see Fig. 3. The ¼" x ¼" tongue on the top edge of each side piece is cut on the circular saw.

The top piece has two ¼" x ¼" blind grooves cut ½" from the side edge and stopping 1" from the front edge into which the side pieces are fastened. A blind dado ¾" wide ¼" deep is made on the bottom side of the top piece to accommodate the center drawer partition, see Figs. 1 and 3. A blind rabbet 1/8" deep is cut on the back edge of the top piece to house the back panel. 1/8" rabbet is also cut on the back edge of each side piece for the back panel.

Four drawer slide frames are made of ¾ x 2" stock. The top drawer frame has an additional center runner for the two top drawers with ¼" x 3/8" short tenons. A groove ¾" wide ¼" deep is made in the center runner of the top drawer frame for the center partition piece. The drawer slide frames are assembled with ¼" x 3/8" mortise and tenons joints, see Fig. 4. The short mortises are made on the circular saw with the two 1/8" outside dado cutters, Photo No.3.

|

For a natural finish, sand thoroughly, breaking all sharp corners and apply two thin coats of white shellac, sanding between each coat and follow with a coat of rubbed effect varnish. For an enameled finish, apply a coat of undercoating tinted similar to the finish coat, followed with two coats of non-toxic enamel. Decals may also be added if desired. |

Tenons are quickly made on the circular saw with the tenoning jig and two blades of the same diameter with a ¼" spacing collar between the blades. Assemble the sides, top and drawer frame units with glue using bar clamps.

The drawers are made with a 1/8 x 1/8" tongue on the drawer front as shown in Fig. 2 and 5-A of the drawing. A finger groove is cut on the face and back side of the three large drawers. Only back side grooves are made on the two top drawers, see Figs. 2 and 5. These finger grooves are made on the circular saw with the No. 35-100 cutters. Be sure to make several light cuts when passing the stock over the moulding cutters to prevent the stock from sol splintering. |

# of

Pieces |

Name |

Size |

| 2 |

Chest Sides |

¾x18x34¼ |

| 1 |

Chest Top |

¾x18x36 |

| 4 |

Drawer Slide Frame (Fronts) |

¾x2x35 |

| 8 |

Drawer Slide Frame (Sides) |

¾x2x15½ |

| 4 |

Drawer Slide Frame (Backs) |

¾x2x31¾ |

| 1 |

Drawer Slide Frame (Center Runner) |

¾x2x13-1/8 |

| 1 |

Top Drawer Separator |

¾x5½x17-7/8 |

| 2 |

Bottom Stretchers |

¾x3x35 |

| 1 |

Chest Bock Panel |

1/8x31½x35½ |

| 2 |

Drawer Fronts |

¾x5x16-7/8 |

| 2 |

Drawer Fronts |

¾x8x34½ |

| 1 |

Drawer Front |

¾x10x34½ |

| 4 |

Drawer Sides |

½x4¼x17-5/8 |

| 4 |

Drawer Sides |

½x7¼x17-5/8 |

| 2 |

Drawer Sides |

½x9¼x17-5/8 |

| 2 |

Drawer Backs |

½x3-5/8x16-3/8 |

| 2 |

Drawer Backs |

½x6-5/8x34 |

| 1 |

Drawer Back |

½x8-5/8x34 |

| 2 |

Drawer Bottoms |

1/8x17-3/8x16-3/8 |

| 3 |

Drawer Bottoms |

1/8x17-3/8x34 |

| 14 |

Glue Blocks |

¾x¾x3 |

|