|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

Here is the orginal article from the

November - December 1958 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

|

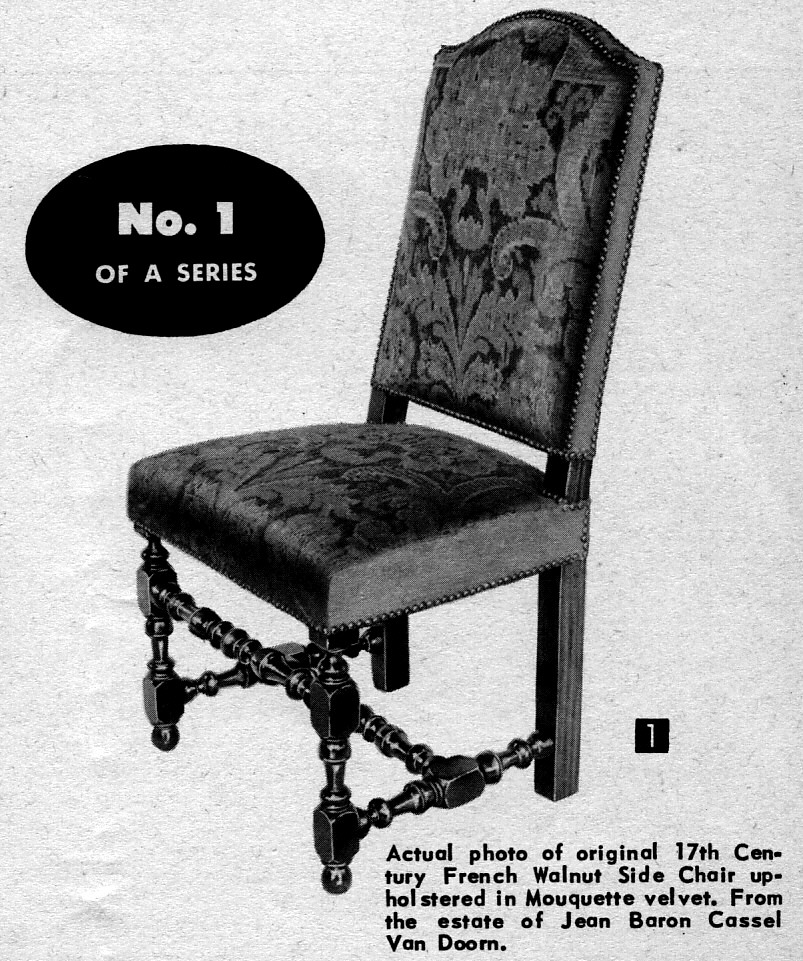

17th Century

Side Chair

This strikingly beautiful and distinctive chair is the first project in a series of antique furniture projects which we plan to feature from time to time. This 17th Century Side Chair is an authentic reproduction of the original as presented by Baroness Cassel Van Doorn to the Department of Fine Arts, Carnegie Institute, Pittsburgh, Pa.

Walnut or mahogany woods are best suited for this project and will blend nicely with a light Mouquette velvet upholstery material.

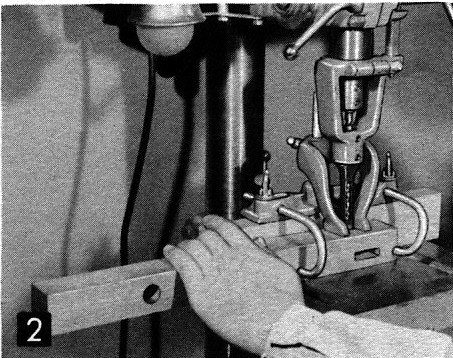

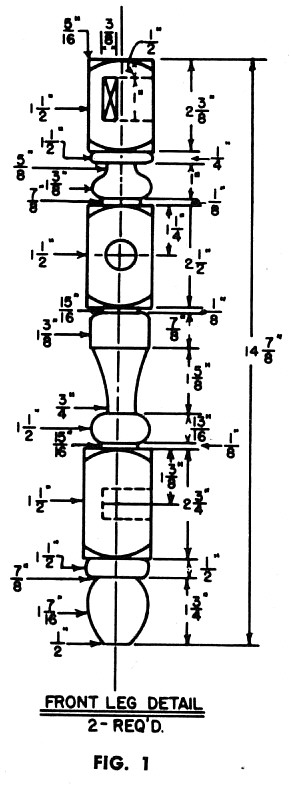

Start the construction of the chair by cutting two pieces of 1½" square stock for the front legs, see Fig. 1. Layout the positions of the two top mortises and the two dowel holes for the stretchers "A" and "C". Then proceed with making these mortise and dowel holes, Photo No.2. The legs are then set up in the lathe and turned to the contours shown in Fig. No. 1 and Photo No.3. The. stretchers are also made of 1½ X 1½" stock and turned to contours shown in Figs. 2, 3 and 4.

|

|

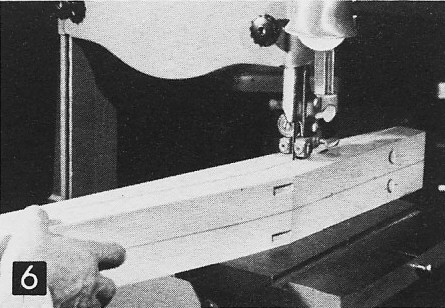

| The rear legs are cut from stock 1¾" thick by 3-3/8" wide by 38" long. The side profiles are marked off, mortised for the side seat rails and bored for turned stretcher (C) and cut on the band saw as shown in Fig. No.6 and Photo No.6. After cutting to shape, these are mortised to take the curved top back piece, bottom back rail and back seat rail. Note that the two side seat rails have angled tenons, see Fig. 7 and Photo No.7. |

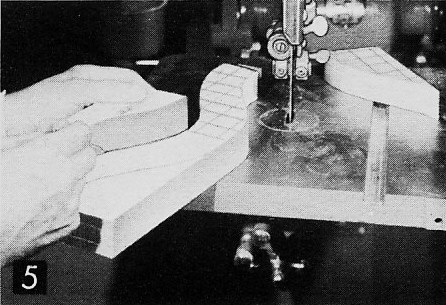

Tenons 3/8 x 1-3/8" long are cut on a piece of stock 1-3/8" thick by 4½" wide by 17¼" long using a tenoning jig and two blades with a 3/8" spacing collar, Photo No, 4. This piece is used for the top rail on the back of the chair. Draw the top and bottom curves using the squares method, Fig. No.5. |

|

Before turning the legs of the chair, they are mortised

on the drill press with a 3/8" hollow chisel and

mortising attachment. Holes for round tenons are

bored on the drill press with a ¾" machine spur bit.

|

|

After all parts have been properly machined, make a dry assembly by clamping the chair together to make sure parts fit. While chair is still clamped together, fit the hardwood corner blocks to the top chair seat rails, see Fig. No.8. Mark each corner block and the corresponding corner for final assembly. These are fastened to the chair rails with #8 x 1¾" flat head wood screws.

To insure a good finishing job it is well to take a light cut with a hand plane on all straight surfaces and sand each piece individually with 3-0 and 6-0 garnet paper, before final assembly. Only slight sanding here and there is necessary after chair has been assembled.

The finish will require a stain followed by the same color paste wood filler to fill the pores of the wood, Two or three thin coats of white shellac are applied sanding or rubbing with 6-0 garnet paper or 4-0 steel wool between coats after the shellac has thoroughly dried. A coat of rubbed effect varnish will give the chair a satin-like finish.

If you are not familiar with upholstery, it is best to have this done by an expert who specializes in this work. Should you wish to tackle the job yourself, there are a number of good books on this subject at your local library or bookstore. |

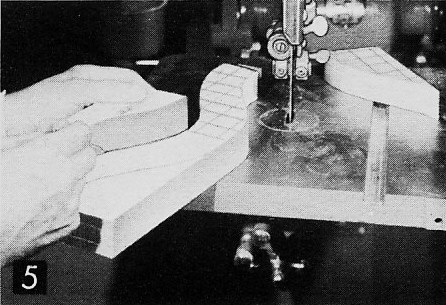

Half of the curved back rail is cut on the band

saw. The cut scrap pieces are then flopped

over on the other side and the other half

of the raIl is traced.

|

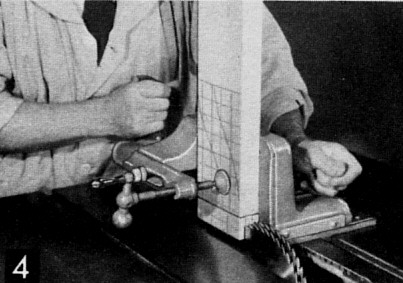

With the two rear leg pieces tacked together,

the outside cut is band sawed first.

The mortise is then made for the side

chair seat stretcher and the dowel hole

is bored for the turned side stretcher.

The back portion of the rear leg pieces

is then cut on the band saw as shown. |

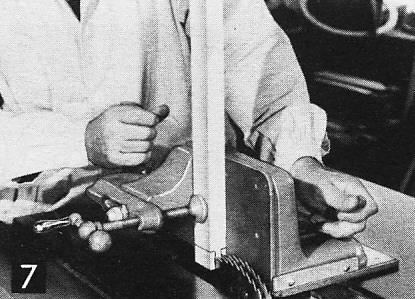

After making the shoulder cuts, a perfect

angle tenon on the two side chair seat

stretchers can be made with the tenoning

chair seat stretcher and the dowel hole and

the saw arbor set at 4 degrees. Two same

diameter blades with a 3/8"spacer

collar are used to make the check cuts. |

|

|

The stretchers and legs are turned on the

lathe. The finishing cuts are being made

with a ¼" round nose tungsten alloy tipped

turning chisel.

Before making the curved cuts on the chair

back roll, tenons are made on the circular

saw with a tenoning iig and two blades mounted

on the sow arbor with a 3/8" spacing collar.

|

|

BILL OF MATERIALS

|

| # Pieces |

Name |

Size |

| 2 |

Front Legs |

1½ x 1½ x 14-7/8 |

| 2 |

Rear Legs |

1¾ x 3-3/8 x 38 |

| 1 |

Top Back Rail |

1-3/8 x 4½ x 17¼ |

| 2 |

Back Seat & Bottom Chair Back Rails |

1 x 1¾ x 17 |

| 2 |

Side Seat Stretchers |

1 x 1¾ x 20½ |

| 1 |

Front Seat Stretchers |

1 x 1¾ x 19 |

| 1 |

Stretcher "A" |

1½ x 1½ x 19 |

| 1 |

Stretcher "B" |

1½ x 1½ x 18 |

| 2 |

Stretcher "C" |

1½ x 1½ x 22 |

| 2 |

Corner Blocks (Front) |

¾ x 1¾ x 3 |

| 2 |

Corner Blocks (Rear) |

¾ x 1¾ x 4 |

|

| Right-click here to download the drawing as an Adobe Acrobat (pdf) file. |

* * * * Click on the drawings above to download a higher resolution picture. * * * *

|

*********** WARNING***********

Read my page on safety before building this item.

|