|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

Maple BREAKFAST

SET

Here is the orginal article straight

from

Book No. 4505, PRACTICAL DELTA PROJECTS

NEW & NOVEL THINGS TO MAKE,

BOOK 5

DELTA MFG. DIVISION

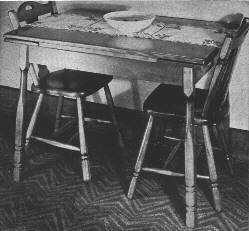

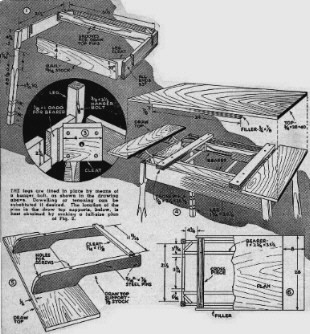

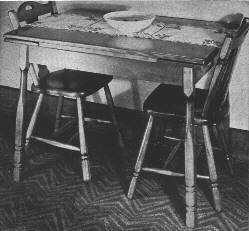

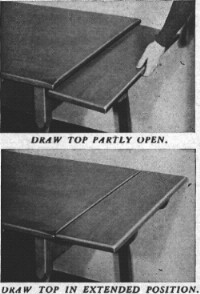

THIS practical set for breakfast nook

or dinette features a draw top table

which gives excellent accommodations with

a minimum of bother in making the

extension. With the top partly drawn, as

shown in one of the photos, the extension

makes a comfortable, if not mannerly, arm

rest for perusing the morning paper.

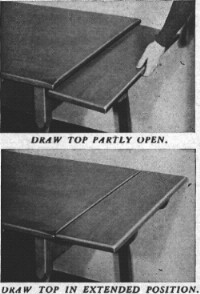

The manner in which the extension is made

is a bit different than the usual draw

top table. As shown in the lower photo,

each leaf is attached to two supports.

These supports are fitted with metal

pins, the pins riding in a pair of

grooves cut in the two longitudinal

members of the frame. |

A delightful set in Colonial styling for

the breakfastnook or dinette. |

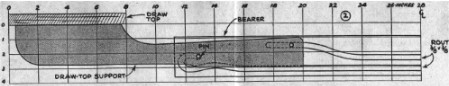

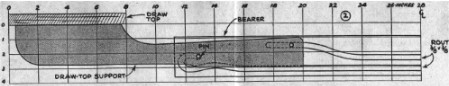

| In order to work

properly, it is necessary to fit the pins

in correct relation to the grooves. Best

results can be obtained if a full-size

drawing is made of the support and

bearer, as shown in Fig. 2 on pa

following page. If a paper pattern is

made of the support, the pattern can be

manipulated over the drawing of the

bearer thus checking the pin positions

and the shape of the track. It is obvious

that each track must have the same amount

of "lift" 7/8 in.) so that the

draw top will be level with the main top

when extended. Once the correct shape of

the track has been plotted, it is a

simple matter to cut a plywood pattern

and rout the grooves on the drill press. |

|

Fig. I shows the general

construction of the table framework,

which is quite simple. The ends of the

rails are cut with the saw table level,

but with the gage set over 3 degrees.

This gives the legs the required outward

tilt. The leg stock is 1-3/4 in square. |

|

Each piece should be carefully

centered, since the turning is largely

confined to knocking off the corners.

After turning, the legs are cut to the

proper length with a compound cut, the

saw table being tilted 3 degrees and the

miter gage set over 3 degrees. Each leg

is held in place by means of a hanger

bolt fitting into a cleat which spans the

rails. This is a simple and substantial

method of construction. but can be

discarded in favor of dowelled or tenon

joints if desired. Through dowels are

particularly simple to fit, and, if

plugged, fit in nicely with the colonial

motif. |

|

Draw Top Arrangement Is

Simple and Foolproof

|

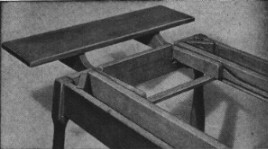

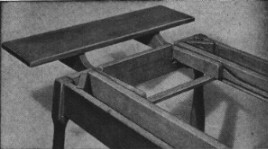

Both bearers are sawed to fit and

routed to take the pins in the draw top

supports. The bearers are fitted into

shallow dado |

|

|

| cuts on the

inner side of the end rails,

adjacent to the openings which

take the supports. Each bearer is

held with two screws, one at each

end, inserted through the rail

near the top edge. Fig. 4 shows

the assembly of the |

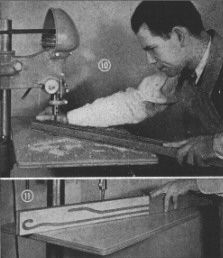

A pattern of

the grooves in the bearer is made

to permit routing on the drill

press. Since the work is

symmetrical, the pattern need be

only a little over hall full

length. |

extension leaves. It will be

necessary to remove one of the

supports from each leaf to permit

fitting, after which the support

is again screw-fastened in place.

Two cross pieces are fitted in

place across the table, the main

top being screw-fastened to

these.

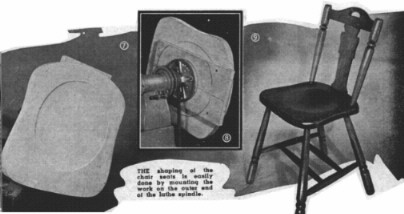

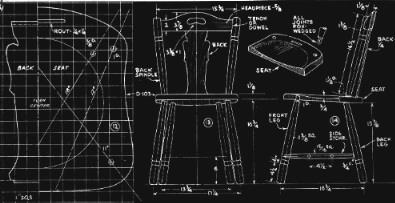

The chairs are made up as shown

in Figs. 12, 13, and 14. It is

advisable to draw a rough

full-size plan, showing all

centerlines, before sawing wood.

It will be noted that the legs

and back spindles are

approximately the same, but vary

a little in length. As with the

table, the turnings are worked

from the |

|

square into the round. The shaping of

the chair seats can be easily done by

mounting the work on the outer end of the

lathe, as shown in Figs. 7 and 8. After

turning, the edges are well sanded down,

especially toward the front edge.

Compound band sawing is required in

making the headpiece.

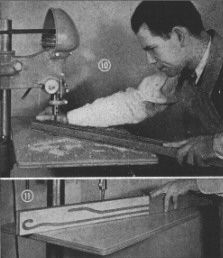

Drilling the various holes at compound

angles in the seat as required for the

legs and back Spindles, is the most

troublesome job in making these chairs.

The set-up is somewhat simplified by the

angles and lines shown in Fig. 12. In

each case, the drill table is tilted as

indicated. The line drawn from the hole

should be lined up with the drill. This

takes care of the compound angle without

the need of blocking up one edge of the

work.

The finish on all pieces is most easily

done with two coats of shellac followed

by a coat of wax. A water or oil stain

should be used to give the wood a

pleasing red-brown tone. The edges of the

table should be sanded to give the

appearance of wear. especially at the

comers. Two or three narrow strips of

felt should be glued on the underside of

the main top at either end so that when

the leaves are returned to position they

will not be scratched on the underside of

the main top |

|

*

* * * * * * * *

Click on the picture above to download a higher

resolution picture.* * * * * *

* * *

|

***********

WARNING***********

Read my page on safety

before building this item.

|