|

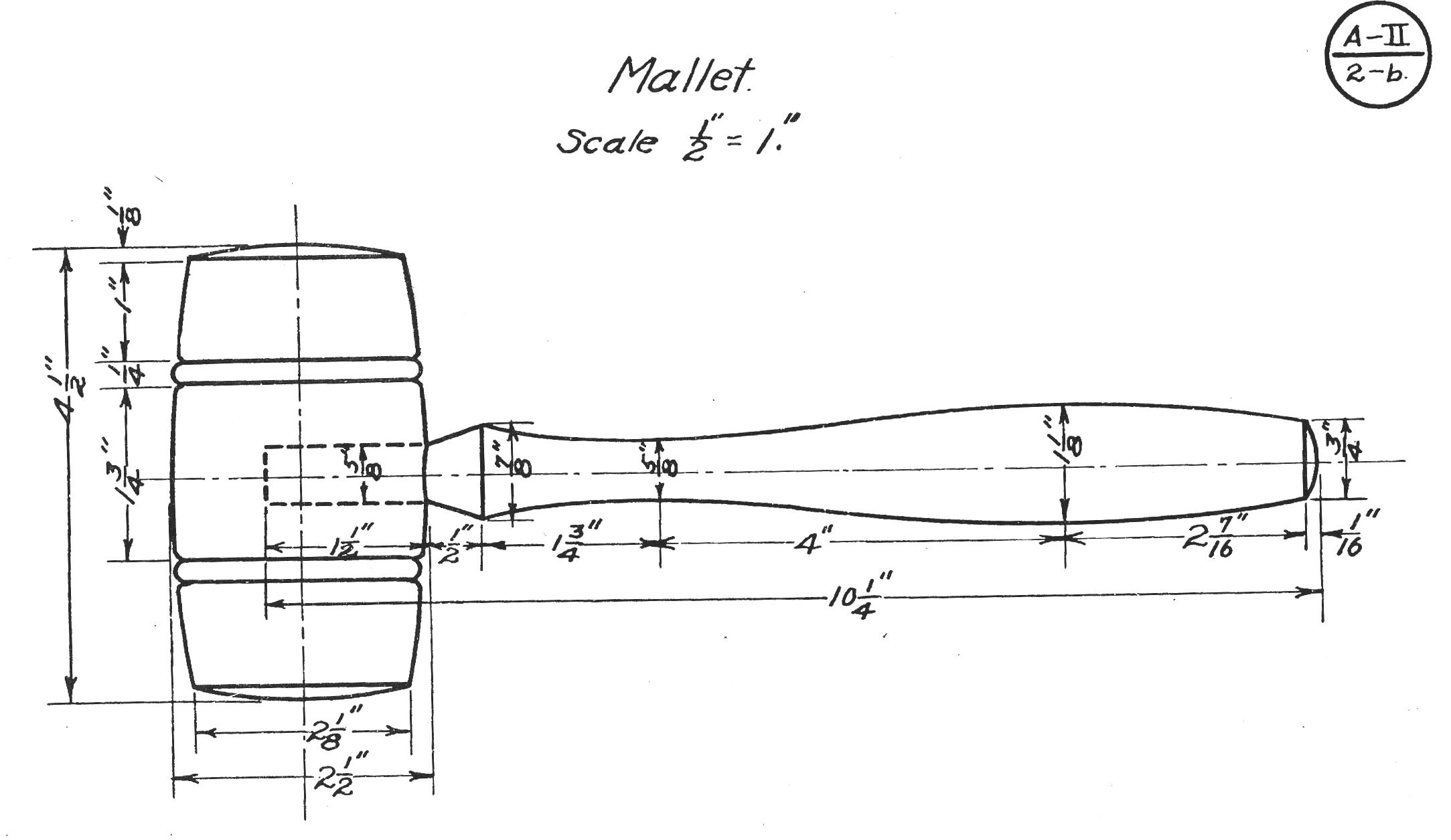

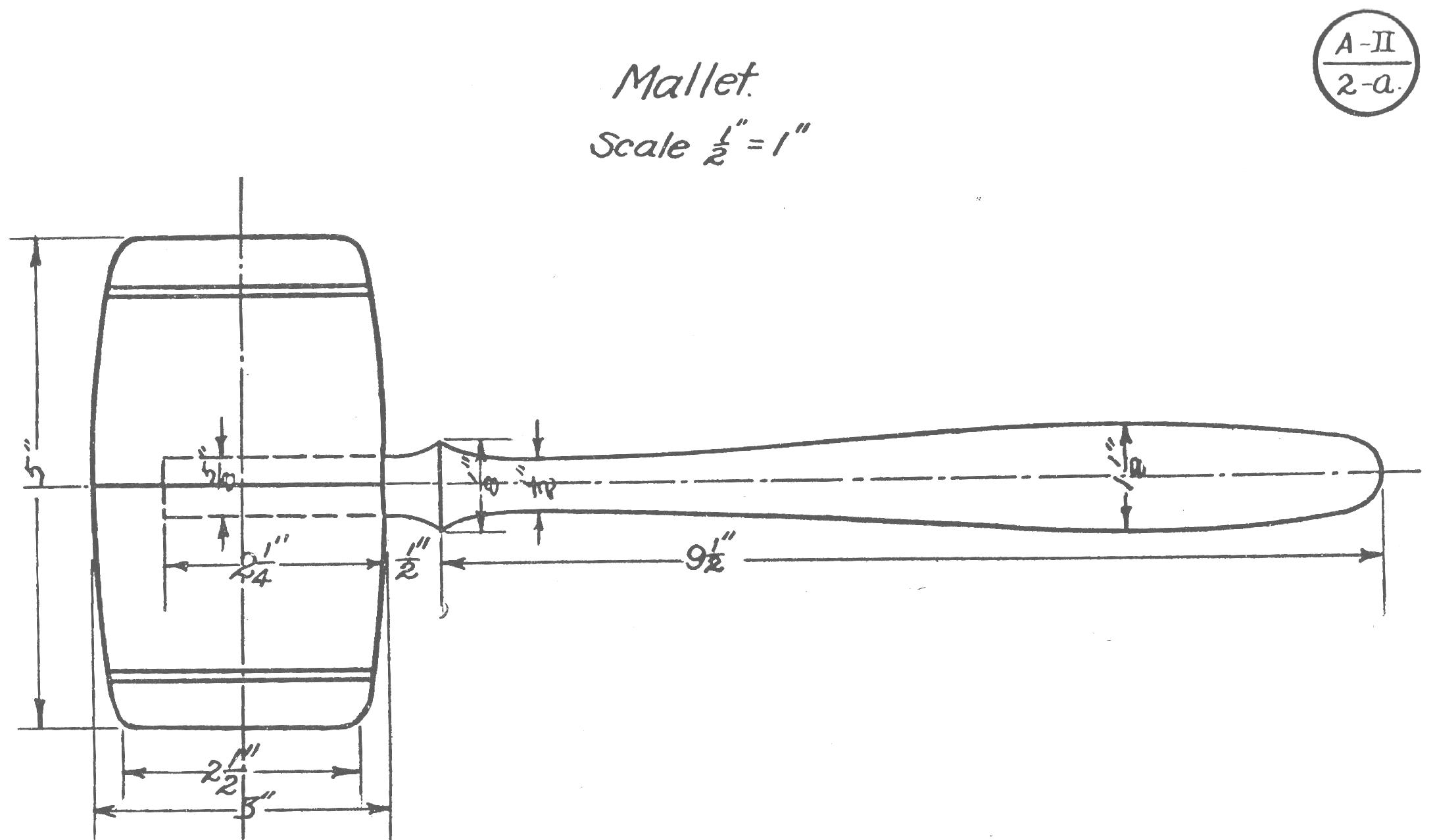

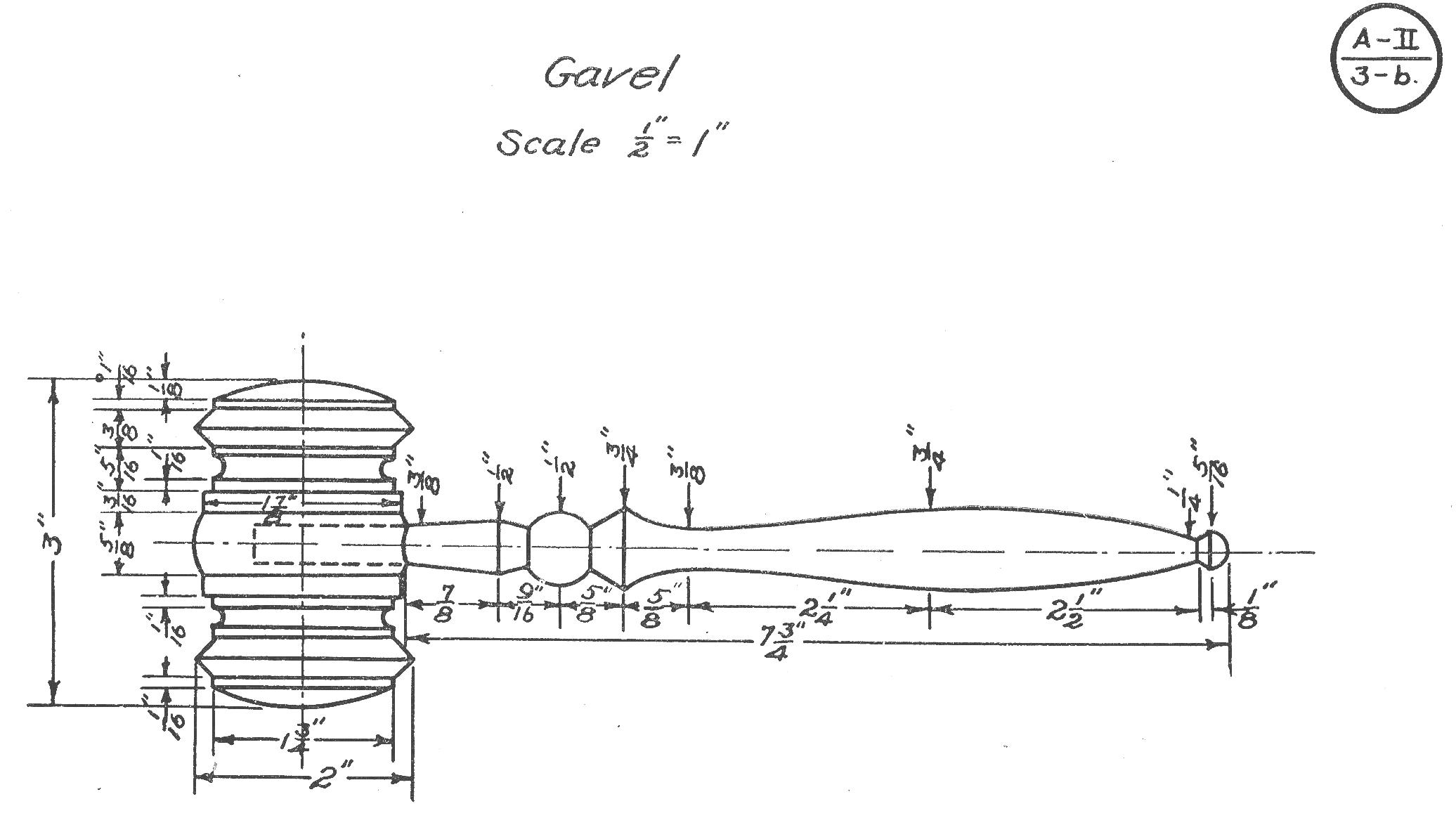

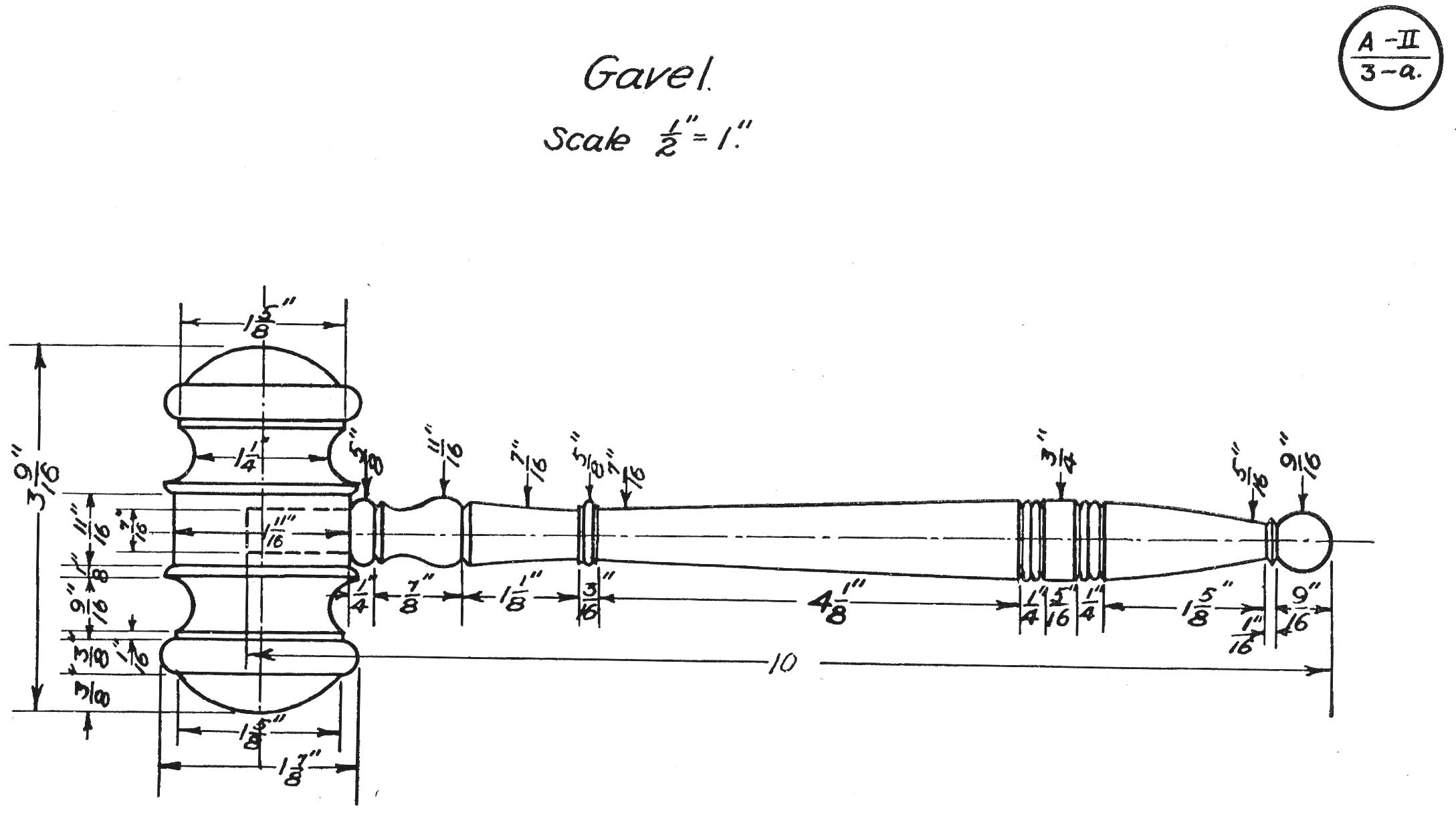

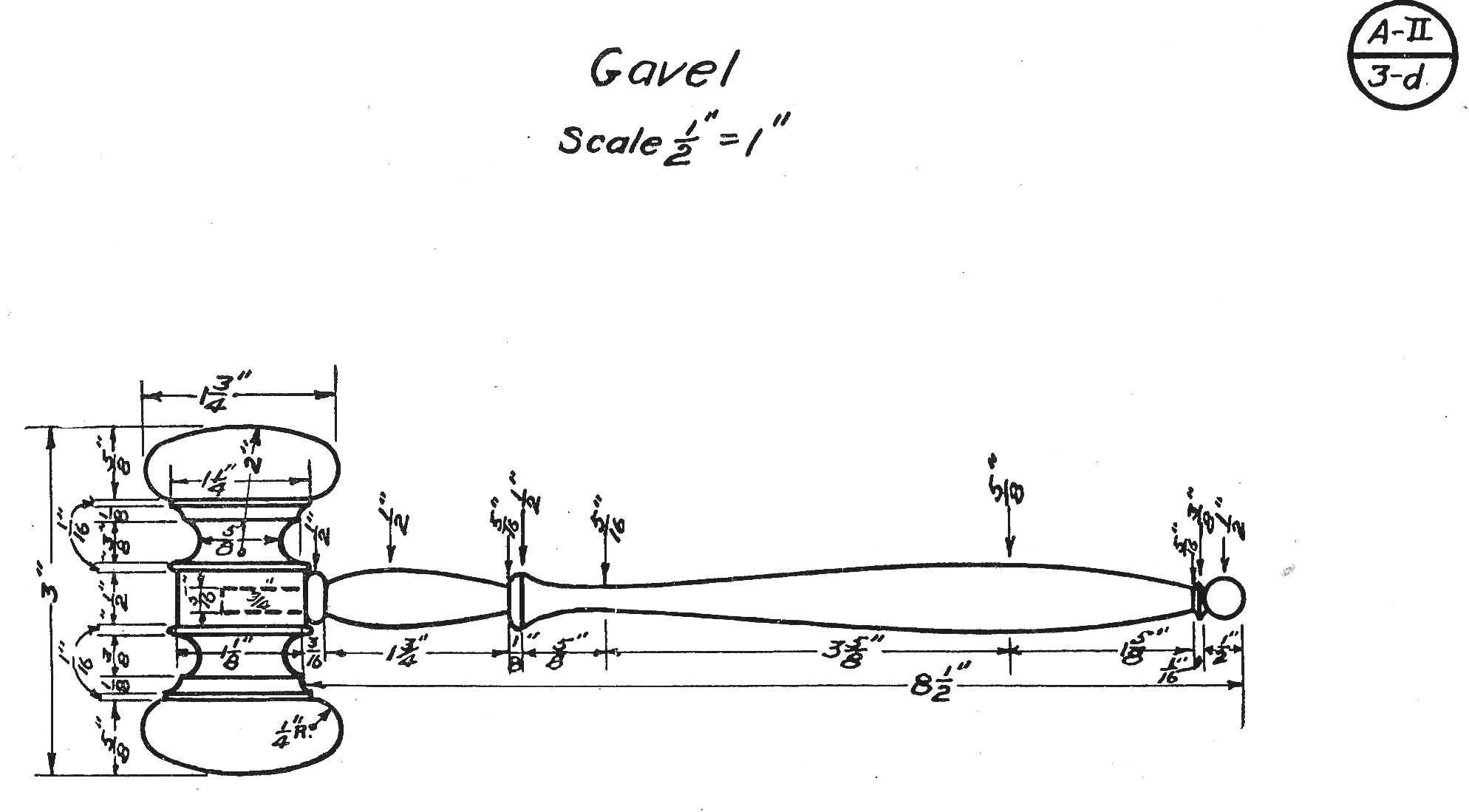

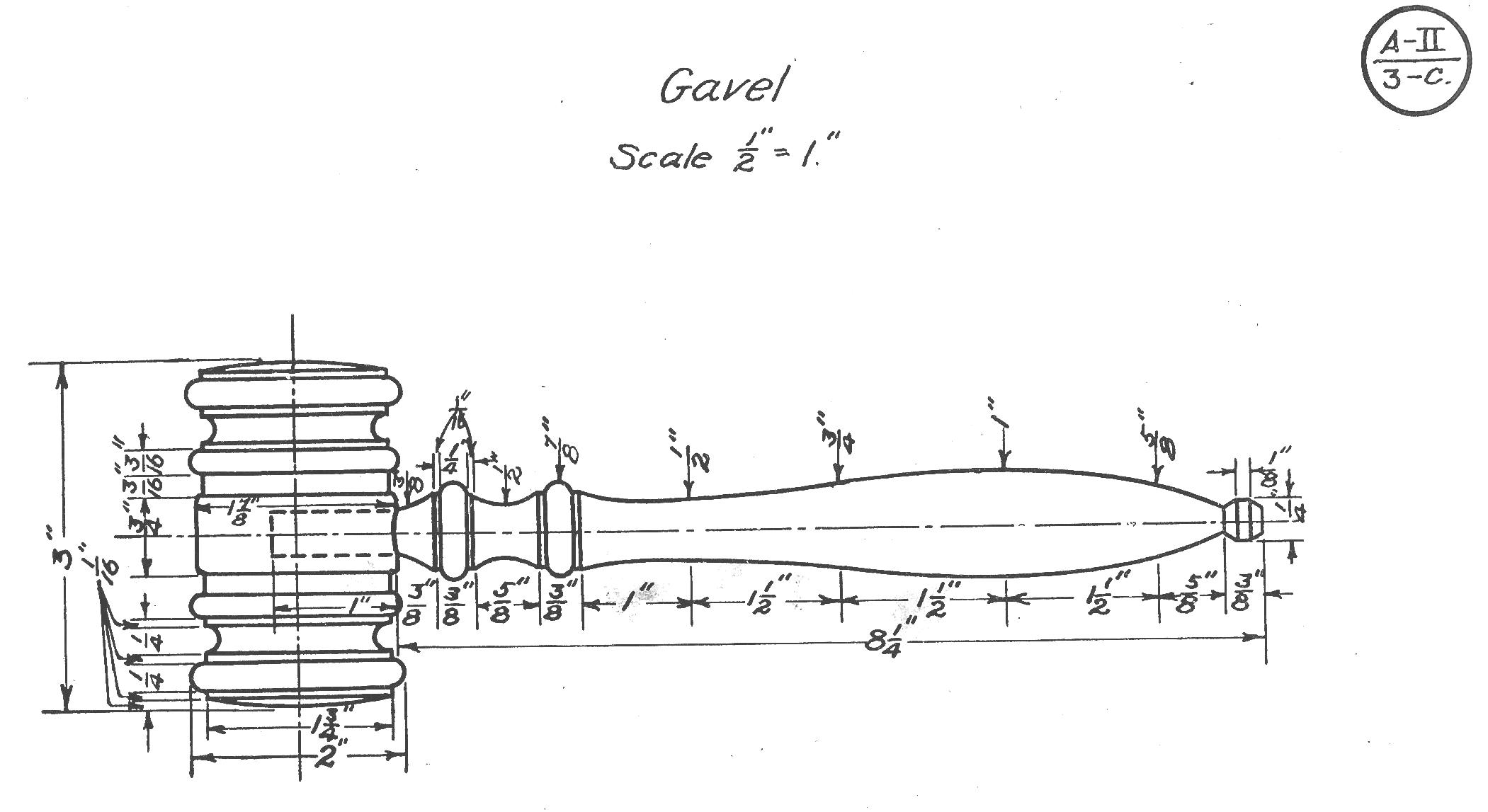

Mallets and Gavels

The biggest source of trouble in these models is getting the handles to fit true. This is caused by not getting the hole in the head straight.

Turn the head to a cylinder 3/16” larger than the finished dimension. Then bore the hole perpendicular to the axis as near as possible, either by leaving it between the lathe centers or by placing it in a vise. The handle is then fitted into the head. A snug fit is necessary. If one side “hangs” or is lower than the other the centers are moved sufficiently to correct it. The head is then turned to exact size and finished.

|

|