Photo #1

Here is a garden or patio furnishing that you will enjoy building. The sides are plywood, supported in back by with, surfaced wheels that will not dig into the law. The curved back has a contour for restful seating. For added comfort, a 2 inch thick pad can be used.

Lay out the pattern of the sides "A" onto some brown wrapping paper using the squares method as indicated in the drawing, Fig, 1. Cut out the paper template then lay out the pattern on a piece of plywood 36 x 48 inches. If layed out as shown (Fig. 4), you will have enough stock left to make the laminated wheels. By changing the position of the blade chuck on the scroll saw, you can cut the side sections apart for easier handling (see photo No. 2). Should you have any irregularities after cutting, they can be easily smoothed by sanding the edges on the drill press using the #830 sanding drum (photo No 3).

Next, cut tapered legs "B" from 1-1/8 inch thick stock (for all solid stock use redwood, cypress, or cedar) see dimension on drawing. Cut all stretches "K", "J", and "H" from 1-1/8 inch thick stock. Bolt the legs to the sides with ¼ x 2¼ inch carriage bolts. The stretchers are screw fastened to the sides with #10 x 2½ inch screws.

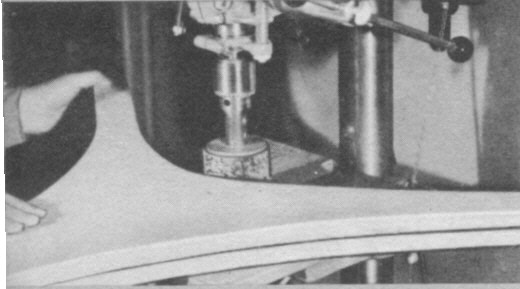

Photo #3

Any irregularity in the curved sections can be easily smoothed down with the Cat. No. 830 3-inch sanding drum on the drill press.

|

The wheels are made of three ¾ inch plywood stock glued together with waterproof glue. These are assembled to the chair as shown in the drawing. Note the ¼ inch tempered pressedwood washers on each side of the wheel. The ¼ inch hardwood dowels hold the wheels in place.

The slats "G"' are beveled on the jointer (photo No, 4) and screw fastened to the sides with #6 x 1¾ brass flat head wood screws. Rosin coated 7 P common nails could be used instead of the screws. Be sure to drill pilot holes in the slats when using nails, use a 3/32 inch drill.

Break all sharp carriers with garnet paper. Apply one or two costs of a wood preservative before applying out-side print. Paraffin applied to the axle on which the wheel turns and to the pressedwood washers will make the wheels turn more freely.

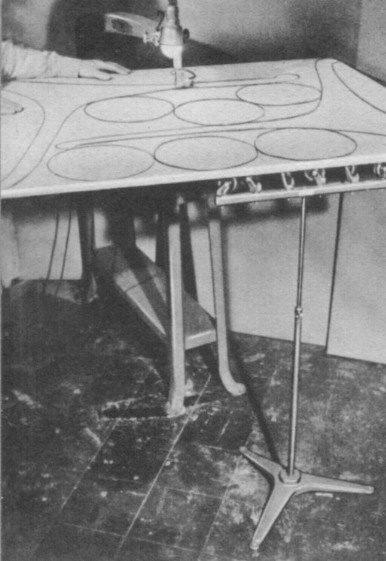

Photo #2

By changing position of the upper and lower chuck on the scroll saw, the panel can be cut apart for easier handling. Note the new Delta Universal Support, Cat. No. 49-375, being used to support the panel while cutting.

Photo #4

By adjusting the jointer fence to 30°, the sides are bevel jointed as shown above.

|